In Chengdu Esimtech Petroleum Equipment Simulation Technology Co., Ltd., also known simply as Esimtech, is a leading provider of simulation systems and services for the petroleum engineering industry. Over the course of more than three decades, Esimtech has been committed to conducting research and developing computerized applications suitable for the oil and gas industry. A variety of drilling and well control simulators is one of the products that Esimtech considers to be their flagship offering. For the purpose of training oilfield workers and evaluating drilling operations, these highly sophisticated simulation systems are utilized all over the world worldwide.

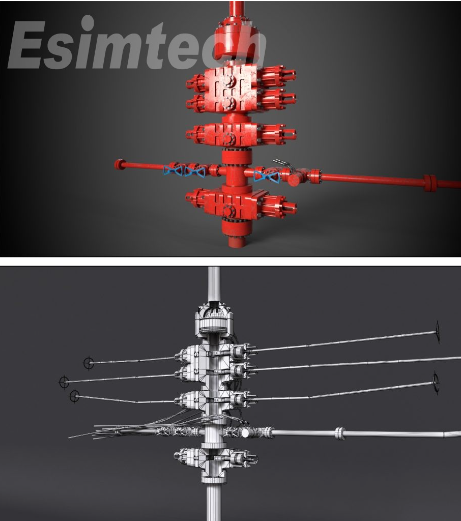

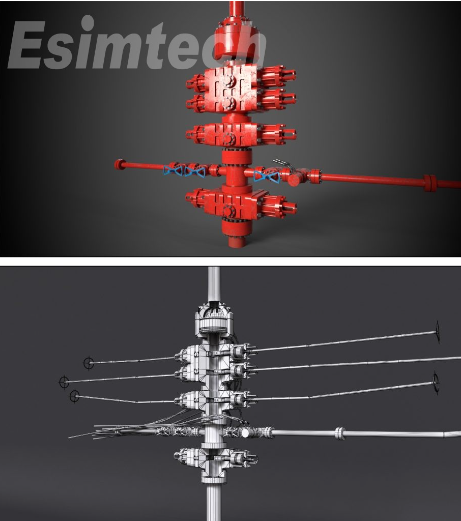

Computer-based systems known as drilling and well control simulators are used to simulate the processes that are involved in the drilling of oil and gas wells. The equipment, procedures, and potential dangers that are encountered during drilling operations are all replicated by these entities. Models are created of the primary elements that make up a drilling rig and wellbore. These elements include blowout preventers, drill pipe, casings, drill bits, pumps, and more. The use of simulators allows for the recreation of situations that involve well control incidents such as kicks, blows, and losses. Because of this, users are able to practice making crucial decisions regarding wellbore monitoring and safety without putting their lives or their equipment in danger.

Exercises Conducted Using Drilling Simulators

1. Esimtech's drilling simulators are primarily utilized for the purposes of training and evaluating one's level of competence

2. It is possible for drilling operators, supervisors, and engineers to acquire practical experience of drilling without having to leave the classroom or training center

3. In the same way that they would interact with a real rig, trainees conduct their interactions with the simulated rig and wellbore

4. In the context of crisis management training, instructors have the ability to present abnormal and emergency scenarios

5. Training participants will have a better understanding of well control principles, drilling procedures, the operation of equipment, and safety protocols as a result of this

Using performance evaluation, the simulators offer an objective method of determining whether or not an individual is competent. During the training process, trainees are evaluated based on their capacity to recognize, react to, and appropriately mitigate well control risks. The development of the hands-on skills necessary for working safely on a drilling rig can be accomplished through simulation training, which is widely regarded as one of the most effective methods. Prior to being deployed into field operations, it provides trainees with the opportunity to learn from their mistakes in a secure and controlled environment.

Esimtech Drilling Simulators Have the Following Key Features:

- Rig configurations that can be customized, including drillship, jack-up, semi-submersible, and land rigs.

A vast collection of wellbore and downhole equipment libraries, which include casing designs, drill strings, BOPs, and other specialized tools.

- All-encompassing operational controls that are designed to simulate the actual control panels, pumps, blowout preventers, and other pertinent equipment found on the rig.

The well diagram and drilling parameters displays are interactive, allowing for real-time monitoring.

- Dynamics that are based on physical principles and can describe fluid flow, cutting transport, drill string vibration, and other phenomena.

- A comprehensive set of well control training scenarios, which may include kicks, blows, losses, wellbore stability events, and other scenarios.

The instructor station provides complete control over the simulation scenarios, parameters, and tools for performance evaluation.

Advanced scenario authoring tools that allow for the creation of individualized simulations that are tailored to the procedures and dangers that are specific to the asset.

through individual and team-based performance evaluations, certification and competency tracking can be accomplished.

Applications for Esimtech's drilling simulators can be found in a wide variety of industries and use cases, including the following:

Training for drilling contractors offers rig crews the opportunity to receive realistic training in both operational and safety procedures prior to deployment.

The theoretical drilling curriculums that are taught in universities and technical colleges are supplemented with practical experience that is gained through hands-on training.

Accreditation of competency levels for crews, supervisors, and other roles is accomplished through the use of competency assessments, which are objective evaluations.

Simulation of new rig layouts and equipment functionality prior to the arrival of the physical rig is referred to as "new rig orientation."

The process of intervention planning involves practicing difficult intervention and workover procedures in a simulated environment that is both safe and secure.

Researchers and developers put new drilling technologies, processes, and procedures through their paces before putting them to the test in the field.

Investigation of accidents involves reconstructing and analyzing previous incidents in order to identify control failures and prevent future occurrences of the same incident.

Capabilities for Customization and Integration Services

Esimtech collaborates closely with its customers to develop drilling simulators that are tailored to precisely meet the operational requirements and asset characteristics of each individual client. The integration of rig modeling, the creation of customized well libraries, scenario authoring, competency tracking systems, and other features are included in this. There is a seamless integration between Esimtech simulators and other training, performance, and information systems because of the way they are designed. Additionally, they provide add-on modules for advanced analytics, multi-user networking, and virtual reality.

With more than thirty years of experience in the development of simulation technologies for petroleum engineering, Esimtech has distinguished itself as the provider of choice for drilling and well control simulators among a large number of leading operators, drilling contractors, and training institutions all over the world. An approach that is safe, effective, and standardized for drilling operations training and competence assessment is provided by their simulation solutions, which are high-fidelity, flexible, and scalable. The customer-centric approach that Esimtech takes and their emphasis on achieving safety excellence through digital innovation continue to bolster the company's leadership position in this specialized field.