Isuzu have earned a global reputation for their exceptional durability and fuel efficiency, particularly under heavy-duty cycles. This performance is a direct result of their robust design and high build standards. At the very heart of this performance is engine compression. Without strong, consistent compression, a diesel engine cannot generate power efficiently. The component directly responsible for creating and maintaining this critical pressure is the piston ring set.

The analysis of piston ring wear is one of the most fundamental aspects of engine diagnostics. This wear is not just a symptom of age; it is a direct measure of the engine's health. Furthermore, when it comes to engine rebuilding, the quality of the replacement piston rings is the single most important factor in determining whether the repair will be successful and durable, or whether the engine will suffer from low power and high oil consumption just a few thousand hours later.

The Three Critical Functions of Isuzu Piston Rings

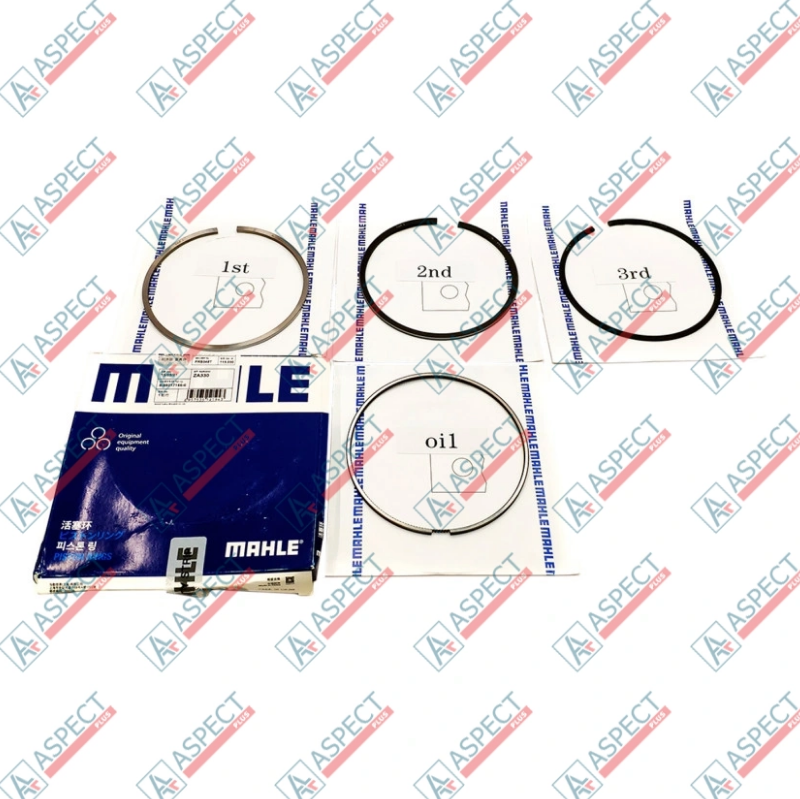

To understand wear, we must first understand the demanding job of a piston ring. It is not one single ring, but a "pack" of three, each with a specialized role:

- Compression Sealing: The top ring (or rings) is the "gas seal." Its primary job is to expand outwards, sealing the microscopic gap between the piston and the cylinder wall. This traps the immense pressure of the combustion gases (often over 1,500 psi) in the combustion chamber, forcing the piston down to create power.

- Oil Control: The bottom ring is the "oil control ring." It is designed to scrape the vast majority of lubricating oil off the cylinder wall on the piston's downstroke, leaving only a microscopic film. This prevents oil from entering the combustion chamber and being burned.

- Heat Transfer: The piston crown absorbs the full heat of combustion. The piston rings are the primary bridge for this heat to transfer from the piston into the liquid-cooled cylinder walls, protecting the piston from melting.

The Direct Link: How Piston Ring Wear Destroys Compression

The link between ring wear and compression loss is direct and mechanical. This wear primarily occurs on the outer "face" of the ring—the part that slides against the cylinder wall.

- Mechanism of Wear: Over millions of cycles, the ring's sharp sealing edge is gradually rounded off. The ring itself also loses its "radial tension"—the inherent spring-like force that pushes it outwards against the cylinder wall.

- The Result: "Blow-By": As this wear creates a gap, the high-pressure combustion gases are no longer sealed. Instead of pushing the piston down, they "blow by" the worn rings and escape into the engine's crankcase. This phenomenon is known as "blow-by."

- Symptoms of Lost Compression:

- Loss of Power: The engine feels weak, especially under load, because the energy of combustion is literally leaking away.

- Hard Starting: A diesel engine like an Isuzu relies entirely on high compression to generate the heat needed to ignite the fuel. Low compression means the air in the cylinder doesn't get hot enough, causing difficult or failed starting, especially in cold weather.

- Increased Crankcase Pressure: All that escaping blow-by gas pressurizes the crankcase, often pushing oil out of seals or causing visible "smoke" or "fumes" from the oil cap or crankcase breather.

Common Causes of Premature Piston Ring Wear

While rings are designed to wear slowly, several factors can accelerate this process dramatically:

- Abrasive Contamination: This is the #1 enemy. Fine dust, silica, or dirt particles that enter the engine's intake become a "grinding paste." This paste gets trapped between the rings and the cylinder wall, acting like sandpaper and rapidly scouring both components.

- Improper Lubrication: Using the wrong specification of engine oil (or extending oil change intervals) causes the oil film to break down under high heat and pressure. This leads to direct metal-on-metal contact between the rings and the cylinder liner, causing rapid scuffing and wear.

- Overheating: An overheating event can cause the piston to swell and the rings to lose their tension, leading to permanent damage and a poor seal.

- Fuel-Related Issues: A faulty fuel injector that is "dribbling" fuel can wash the protective oil film off the cylinder wall, leading to severe localized wear on the rings in that specific cylinder.

The Quality Factor: How Parts Quality Affects Compression

During an engine rebuild, an Isuzu engine's compression can only be restored if the replacement parts are of sufficient quality. Using cheap, low-quality piston rings is a catastrophic mistake. Here is why:

- Material and Metallurgy: A piston ring is not just a piece of metal; it is a high-engineering spring. Genuine Isuzu parts are made from high-grade nodular cast iron or steel alloys with a specific metallurgy that ensures they maintain their radial tension even at extreme operating temperatures. Low-quality rings are often made from inferior materials that "go flat" (lose their spring force) when hot, leading to massive blow-by and low compression almost immediately after the rebuild.

- Surface Coatings: Modern Isuzu engines use sophisticated surface coatings on their rings to fight wear. These can include hard chrome plating, nitriding, or PVD (Physical Vapour Deposition) coatings. These ultra-hard, low-friction surfaces are designed to survive in the abrasive environment. Cheap rings often have no coating at all, or a simple "flash" coating that wears off in a few hundred hours, leading to rapid wear.

- Manufacturing Tolerances: The shape and "end-gap" of a piston ring are machined to tolerances of a few thousandths of an inch. Poorly manufactured rings may have an inconsistent profile that never seals correctly, or an end-gap that is too large, creating a built-in leak path for compression from day one.

In short, a high-quality part creates a perfect seal and is engineered to maintain that seal for thousands of hours. A low-quality part creates an imperfect seal from the start and loses its sealing ability quickly, resulting in a failed rebuild and a return of all the original low-compression symptoms.

Our company, Aspect Plus, specializes in providing genuine Isuzu spare parts and high-quality, certified analogues that meet the exact material and engineering specifications required to restore an engine's compression to factory levels.

Conclusion

In an Isuzu engine, the piston rings are the final, critical seal that turns combustion pressure into usable power. The analysis of their wear is the most direct way to diagnose the health of an engine's "bottom end." When wear occurs and compression is lost, a rebuild is necessary. However, the success of that rebuild is entirely dependent on the quality of the new rings. Using inferior parts is not a "saving"; it is a guarantee of a repeat failure. Investing in genuine Isuzu or premium OEM-spec parts is the only way to ensure the engine's power, efficiency, and long-term reliability are truly restored.

For expert consultation on engine diagnostics and a reliable source for high-quality Isuzu engine components, contact the specialists at Aspect Plus.