As the demand for lithium-ion batteries continues to surge, particularly in sectors like electric vehicles, the need for efficient and effective production methods has never been more critical. Mikrouna offers comprehensive solutions for lithium-ion cylindrical battery cell pilot lines, designed specifically for research and development laboratories. This article explores the key processes involved in assembling cylindrical battery cells and the significance of pilot lines in advancing battery technology.

1. Overview of the Cylindrical Battery Pilot Line Process

The Mikrouna cylindrical battery pilot line encompasses a series of essential steps that ensure the successful assembly of high-quality lithium-ion batteries. The main processes include:

- Cell Short Circuit Testing

- Tab Welding

- Assembly of Rolling Groove

- Vacuum Baking

- Vacuum Injection

- Standing

- Covering (or Closing)

- Laser Welding Cap

- Cylindrical Sealing

Each step plays a vital role in achieving optimal performance and safety in the final product.

2. Cell Short Circuit Testing

The first step in the pilot line process is conducting short circuit tests on the cells. This crucial test evaluates how the battery reacts under short circuit conditions, ensuring safety and reliability before proceeding to further assembly.

Key Input: Pouch battery cells

Output: Safety assessment results

3. Tab Welding

Following testing, tab welding connects the positive and negative electrodes of the battery to the external circuit. This step is essential for establishing a good electrical connection, which is vital for battery performance.

Key Input: Electrode sheets

Output: Welded tab connections

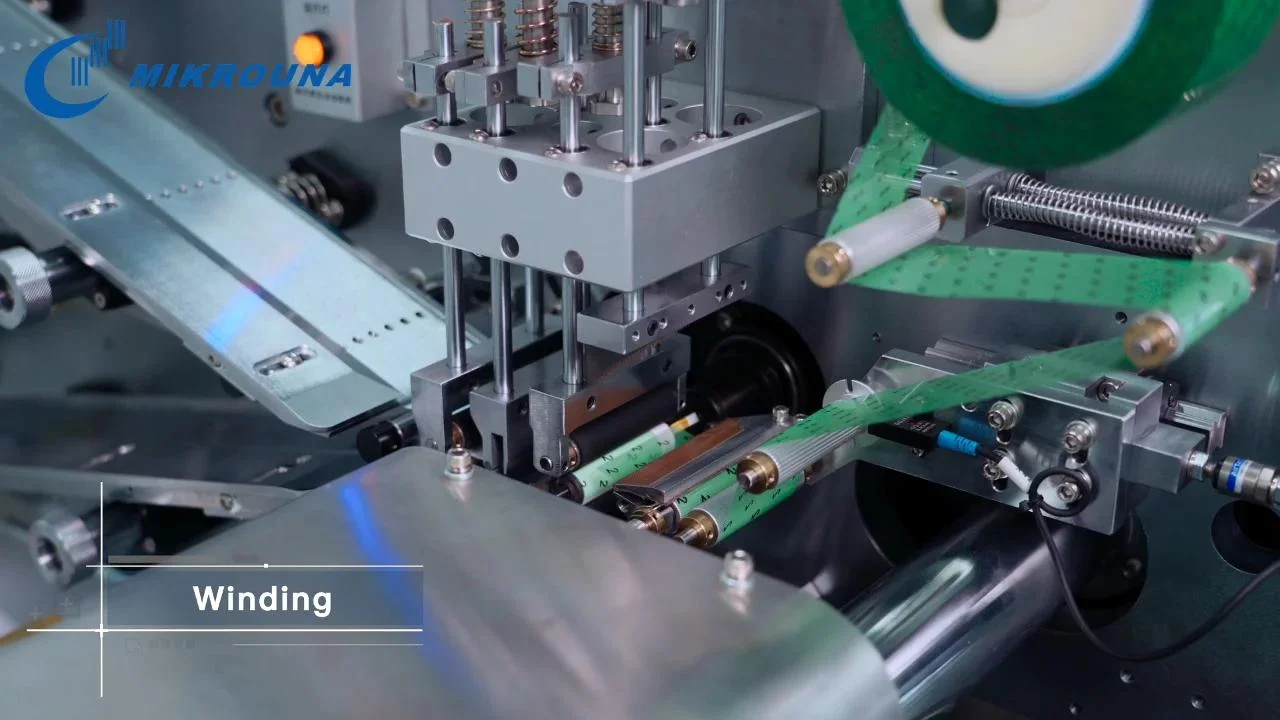

4. Assembly of Rolling Groove

In this stage, various components of the battery are precisely assembled to ensure structural stability and sealing integrity. Proper assembly is critical to prevent leaks and ensure long-term performance.

Key Input: Battery components

Output: Assembled rolling groove structure

5. Vacuum Baking

Vacuum baking is performed to remove any internal moisture and impurities from the assembled batteries. This step is crucial as moisture can significantly impact battery performance and safety.

Key Input: Assembled battery cells

Output: Moisture-free battery cells

6. Vacuum Injection

Once baking is complete, electrolyte injection occurs under vacuum conditions. This process ensures that the electrolyte fills all voids within the cell, which is essential for optimal operation.

Key Input: Electrolyte solution

Output: Fully filled cylindrical cells

7. Standing

After injection, the cells are allowed to stand for a specified period. This standing time helps ensure uniform distribution of the electrolyte throughout the cell, enhancing performance consistency.

Key Input: Assembled battery cells

Output: Uniformly soaked electrodes

8. Covering (or Closing)

The next step involves placing a cover on the closed battery to protect its internal structure from external elements. This cover is vital for maintaining cell integrity during operation.

Key Input: Battery assembly

Output: Covered cylindrical cells

9. Laser Welding Cap

Laser welding technology is employed to securely weld the battery cap in place. This method ensures a strong seal that prevents leaks and enhances safety.

Key Input: Battery cap

Output: Welded cap on cylindrical cells

10. Cylindrical Sealing

The final sealing process is performed on the battery to complete production. Proper sealing is crucial for maintaining pressure within the cell and preventing contamination.

Key Input: Assembled cylindrical batteries

Output: Sealed and finished cylindrical batteries

Application Scenarios of Cylindrical Battery Experimental Lines

The cylindrical battery experimental line is widely used across various industries, including:

- New Energy Vehicles (NEVs): With their high energy density and long life, cylindrical batteries are favored in electric vehicles.

- Portable Electronic Devices: From smartphones to laptops, cylindrical batteries are integral to powering modern electronics.

The existence of experimental lines enables manufacturers to conduct in-depth research on new materials, processes, and technologies, continuously optimizing product performance and enhancing market competitiveness.

Conclusion

Lithium-ion cylindrical battery cell pilot line solutions are essential for advancing battery technology and meeting growing market demands. Each step in the assembly process—from short circuit testing to final sealing—contributes significantly to ensuring high-quality performance and safety in lithium-ion batteries.

At Mikrouna, we are committed to providing innovative solutions for lithium-ion cylindrical battery cell assembly tailored for laboratory needs. If you’re looking for expert guidance or equipment for your cylindrical battery production processes, contact us today! Let Mikrouna help you achieve excellence in your battery production endeavors with our state-of-the-art pilot line solutions designed specifically for your requirements.