At present, the global Freight Railcar Repair Market is gaining momentum on account of rapid infrastructure developments, technological advancements, and industry-level collaboration efforts. While rail freight keeps playing an essential role in global logistics, the demand for railcar operations is increasing with respect to reliability, safety, and efficiency, thus leading to increased investment in both scheduled maintenance and advanced repair solutions. This growth is highly supported by emerging markets in the Asia-Pacific region with large railway development projects underway. Smart applications involving IoT and predictive maintenance systems serve as an additional driver that can foster growth through to 2033.

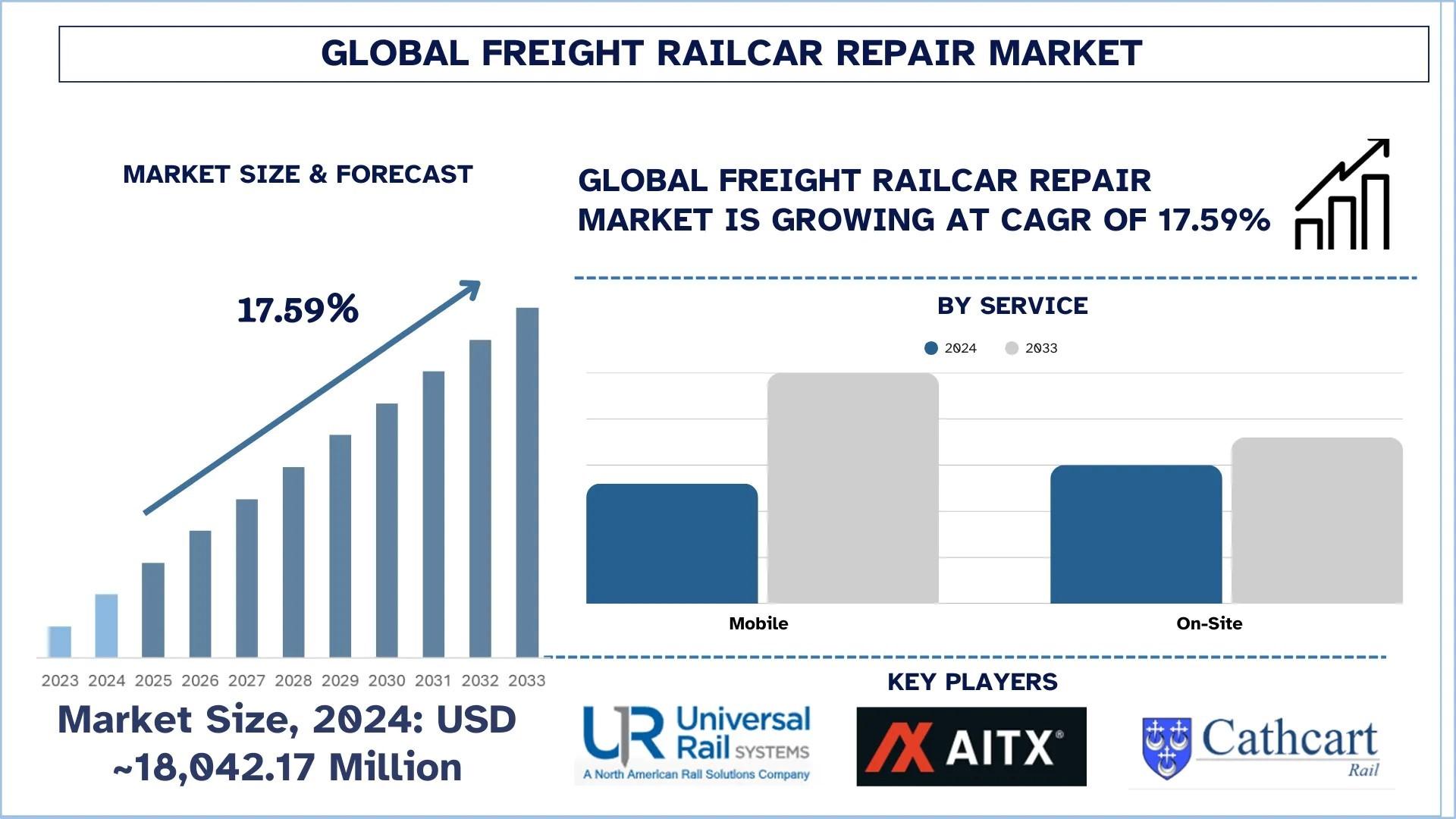

According to the UnivDatos, the rising investment in railcar fleet and route expansion, and increasing demand for timely repair and predictive maintenance of railcar freight, the demand for Freight Railcar Repair is further anticipated to grow. As per their “Freight Railcar Repair Market” report, the global market was valued at USD 18,042.17 million in 2024, growing at a CAGR of about 17.59% during the forecast period from 2025 - 2033 to reach USD million by 2033.

Expansion of Rail Infrastructure:

The insistent growth of railway infrastructure may be referred to as one of the major causes of the freight railcar repair market growth. Investments by governments and private entities all around the world are excessive, being incurred towards the development of new rail lines, the upgrading of already existing tracks, and modernizing the terminals within existing rail systems to increase freight capacity. With these infrastructure developments, there typically occurs a release of new railcar demand; the consequence is heightened demand for maintenance and repair jobs directed toward the safety, reliability, and regulatory standards compliance of the railway system. As emerging economies lay emphasis on the enhancement of their transport networks to spur industrial growth and trade, there has been an increasing demand for efficient railcar repair solutions. Besides, in turn, the upgrade of infrastructure itself usually incorporates high-end technology, which requires specialized repair and diagnostic features. The trend incentivizes a true volume of repair jobs and forces service providers into innovations and extension of their technical know-how in close correspondence with the emerging demands of the freight rail industry.

For More Detailed Analysis in PDF Format, Visit- https://univdatos.com/reports/freight-railcar-repair-market?popup=report-enquiry

Latest Trends in the Freight Railcar Repair Market

The increasing Adoption of IoT sensors, predictive maintenance software:

The increasing adoption of smart technologies such as IoT sensors, predictive maintenance software is anticipated to further support the market growth of the freight rail repair market. These sensors help in understanding the possible wear and tear of components, non-functioning of critical components, etc., as well as any type of structural damage, i.e., internal or external damage, thereby helping the railways to understand the requirement of timely repair work for smoother operations.

Additionally, these technologies help in increasing the lifecycle of freight and changing the repair work from reactive to proactive, many more operators are anticipated to follow suit. With the continued modernization of railways both in terms of integration of these systems in the legacy fleet as well as by the integration of newer freight models, the collected data will help the operators to move towards predictive maintenance. This would help create the demand for skilled technicians, sensor-based diagnostics, as well as timely freight rail repair in the long run.

Partnership & Collaboration Among Industry Stakeholders:

Partnership & Collaboration among the key industry stakeholders such as railway operators, government, repair services providers, predictive maintenance software providers, etc., is one of the key trends that would improve maintenance practices and improve the market expansion. Many of the rail operators are collaborating with the technology provider companies for the easy integration of the technologies to reduce the risk of downtime of railway freight, as well as improving the operational efficiency through predictive maintenance.

· For instance, in 2025, Texmaco Rail & Engineering from India and Nevomo signed a strategic Memorandum of Understanding (MoU) with Nevomo. This collaboration is in line with the integration of advanced technologies for fleet maintenance, autonomous freight movement, as well as ultra-high-speed rail solutions.

Additionally, many of the leading rail service providers in North America, Europe, and the Asia-Pacific region are also moving towards strategic collaboration to improve their freight maintenance, which would be one of the notable trends to fuel the market growth in the coming years.

Regional Market Growth

The Asia-Pacific freight railcar repair market has held a dominant market share across the globe. With the high presence of railway freight as well as the largest railway network, the freight railcar repair has benefitted enormously in the Asia-Pacific region. Countries such as India, China, South Korea, Australia, Japan, Indonesia, etc., are some of the countries with dense populations and rising investment by the governments in the expansion of railway infrastructure.

Related Reports:

Reach Stacker Market: Current Analysis and Forecast (2022-2030)

Rail Wheel Market: Current Analysis and Forecast (2022-2030)

Rail Saw Market: Current Analysis and Forecast (2024-2032)

Railway Wiring Harness Market: Current Analysis and Forecast (2023-2030)

Railway Management System Market: Current Analysis and Forecast (2023-2030)

Some of the recent developments in the Asia-Pacific region are:

· In 2025, according to the China Railway Group, the country is planning to build a world-class railway infrastructure of 180,000 km, including 60,000 km of high-speed railway infrastructure, to improve both cargo and passenger movement in the country.

· In 2025, the Cabinet Committee of Economic Affairs India approved four railway projects with a total cost of ~USD 2.2 billion (INR 18,658 crores). The respective projects, which include around 15 districts across states, including Maharashtra, Odisha, and Chhattisgarh, will further expand the Indian Railways network by approximately 1,247 km.

Considering all the shifts in terms of investment and expansion in the existing railway network in the key countries of the Asia-Pacific region, the demand for the freight railcar repair market is on the rise during 2025-2033.

Expansion of Rail Infrastructure Fuels Repair Demand

The global freight railcar repair market is growing steadily as infrastructure development is booming as well as technology is advancing, and alliances are being forged. Shippers are making an incremental appeal for safety, efficiency, and close maintenance as freight rail forms an integral part of any sustainable logistics network. Emerging economies, especially in the Asia-Pacific region, are actively undertaking large-scale infrastructure development and smart technology adoption. These very developments are not only increasing the demand for traditional upkeep practices but are also creating an environment where data-driven predictive repairs will be the norm in the industry. The next decade looks promising for innovation, skilled workers, and extension into new markets.

Contact Us:

UnivDatos

Contact Number - +19787330253

Email - contact@univdatos.com

Website - www.univdatos.com