Manufacturing industries worldwide are undergoing a seismic shift driven by advanced technologies, and automation stands at the forefront. As digital transformation gains momentum, the ways companies handle materials and organize assembly operations are evolving rapidly. This transformation isn't just about replacing labor but reimagining processes for better speed, safety, and sustainability.

Smart Integration in Modern Manufacturing

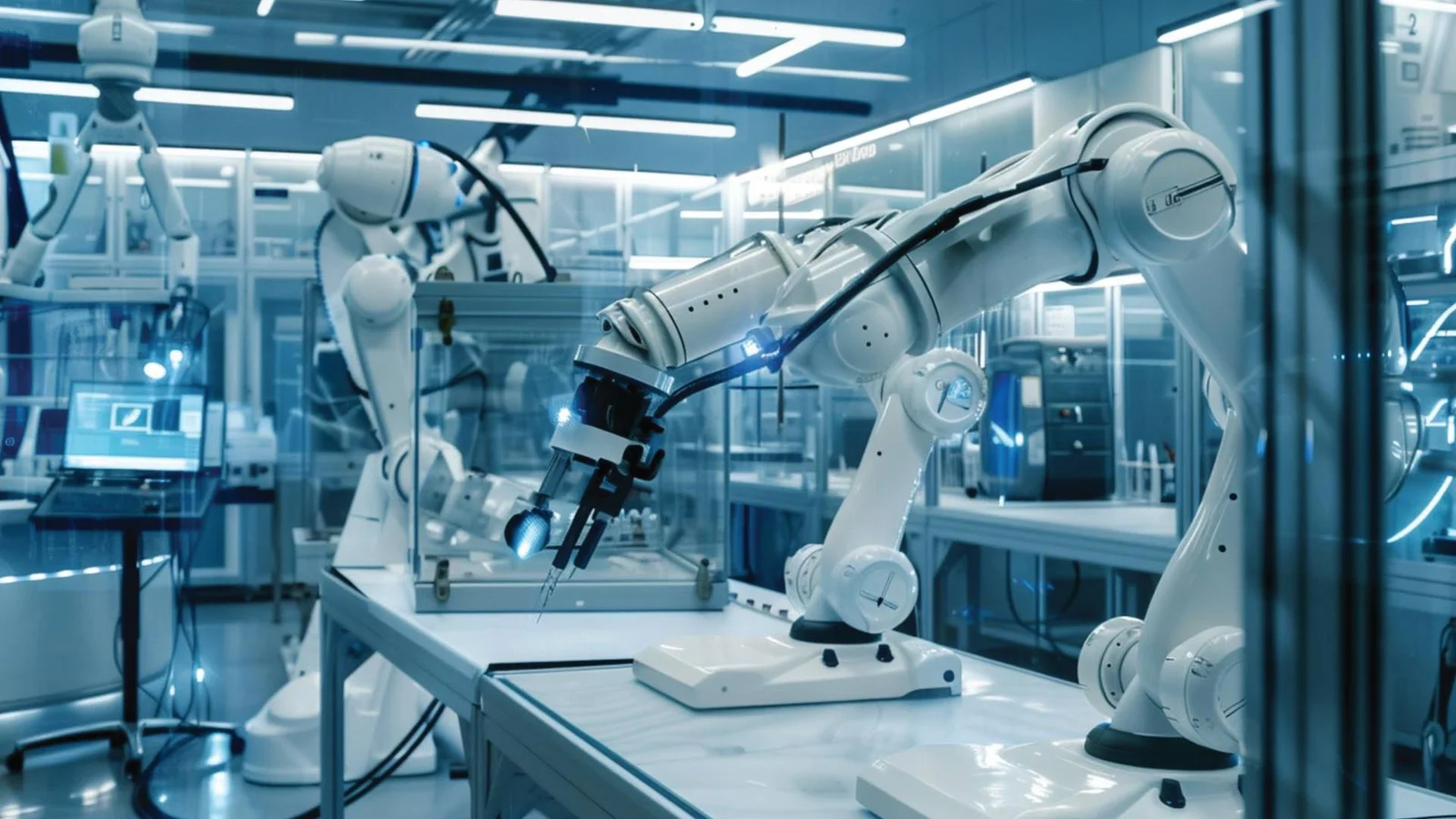

Automation is no longer limited to isolated tasks. It has evolved into a connected ecosystem that integrates robotics, sensors, artificial intelligence, and machine learning. Smart systems communicate across supply chains to anticipate needs, allocate resources, and optimize flows. Automated guided vehicles (AGVs) and robotic arms work in harmony, responding to real-time data inputs that minimize waste and delays.

Efficiency Gains Across Assembly Lines

The hallmark benefit of automation in material handling and assembly is unprecedented efficiency. Automated systems streamline repetitive and precision-based tasks, reducing the time and cost associated with manual labor. High-speed robotic assembly lines enable consistent output, minimizing errors that often occur with human intervention. Material handling becomes seamless, especially when combined with advanced conveyor systems, real-time tracking, and inventory control technologies.

Reducing Downtime and Human Error

Human error and equipment downtime have historically been the Achilles’ heel of production environments. Automation addresses these issues head-on. Predictive maintenance powered by IoT devices identifies wear and tear before breakdowns occur. With fewer human-dependent processes, operations experience fewer interruptions, leading to increased reliability and operational uptime. In hazardous environments, automation further protects human workers by taking over dangerous or ergonomically challenging tasks.

Workforce Evolution in an Automated World

While automation shifts certain roles, it does not eliminate the need for human workers. Instead, it fosters a workforce evolution. Employees are now required to manage, monitor, and maintain these systems, transitioning from repetitive manual tasks to strategic, technical roles. This shift necessitates upskilling and training programs that empower workers to thrive alongside intelligent machines.

Sustainability and Automation

Automation also supports sustainability goals in manufacturing. With optimized resource usage, reduced waste, and energy-efficient systems, companies are aligning operations with environmental responsibilities. Smart automation reduces overproduction and enables precision manufacturing that conserves raw materials and energy. The result is a more eco-conscious supply chain with a lower carbon footprint.

Industry-Specific Applications and Innovations

Different sectors are leveraging automation uniquely. In automotive manufacturing, robots assemble components with extreme precision. In warehousing, automation streamlines picking, packing, and shipping processes. Even in electronics, micro-assembly and inspection tasks are now handled by advanced robotic systems. As these technologies evolve, we can expect to see more adaptive, AI-powered systems capable of learning from operational data and continuously improving performance.

For more info

https://bi-journal.com/how-automation-is-changing-material-handling-and-assembly/

Conclusion

Automation is not simply a trend but a transformative force redefining how materials are handled and how assemblies are structured. It boosts operational efficiency, minimizes errors, enhances safety, and opens doors to more sustainable practices. As industries continue to adopt these innovations, the synergy between humans and machines will create a future of manufacturing that is smarter, faster, and more resilient.