In automated and tension-controlled machinery, the Magnetic Powder Clutch plays a significant role in ensuring smooth torque transmission. A trusted supplier like Cbbmachine provides this type of clutch to support industrial systems requiring accurate, stable motion control without excessive mechanical stress.

Unlike traditional friction-based mechanisms, this clutch design employs magnetically activated powder to establish a controlled connection between driving and driven elements. This principle allows for a gradual and proportionate response, minimizing sudden movements or system shocks. Industries such as printing, film winding, and cable extrusion benefit greatly from such seamless transitions.

One distinct advantage lies in the clutch's ability to deliver torque consistently, regardless of changes in rotational speed. This ensures that processes remain predictable, even under fluctuating load conditions. Additionally, by eliminating the need for direct mechanical contact, the clutch reduces internal wear, which contributes to a longer operational lifespan and lower maintenance requirements.

Temperature control is another key performance factor. As the clutch operates, internal heat generated during engagement is dispersed evenly. This ability to manage thermal buildup allows machines to run for extended periods without risking component failure or operational inconsistency.

Another appealing feature is its quiet, low-vibration functionality. In high-precision setups, excessive vibration can disrupt alignment or compromise accuracy. By operating smoothly and silently, this type of clutch supports overall system stability, even in sensitive environments.

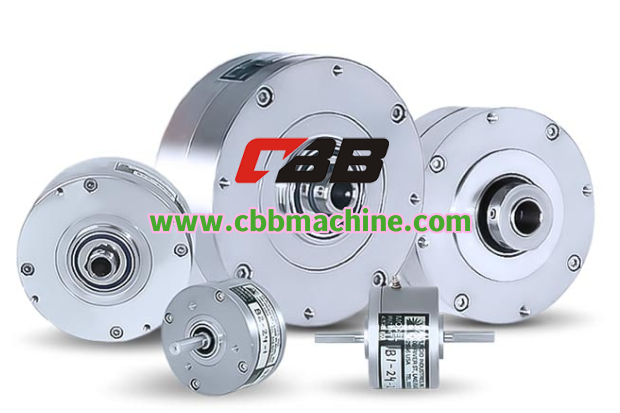

From an integration standpoint, many of these clutches are designed with compact footprints and mounting flexibility. Whether used in new machinery or as part of an upgrade, they often require minimal adaptation. This makes them an attractive choice for manufacturers seeking performance enhancements without major system overhauls.

In selecting the right clutch, several parameters must be evaluated: torque range, response time, duty cycle, cooling method, and system compatibility. Proper calibration and setup are essential to ensure the clutch performs as intended, especially when integrated into automated lines or sensor-driven control loops.

Ultimately, investing in this type of torque transmission solution supports process control, protects material integrity, and reduces operational noise—all of which add value in today's precision-driven industries.

Want to enhance your equipment with smooth, responsive torque control? Visit https://www.cbbmachine.com/product/magnetic-powder-brake-magnetic-powder-clutch/ and see how component-level choices can influence full-system performance—quietly, precisely, and efficiently.