The hydraulic system is the most crucial network in a modern excavator, and for heavy equipment like the Liebherr excavator or crane, its flawless operation is non-negotiable. It provides the immense power for digging, lifting, and swinging, directly impacting a project's productivity and profitability. However, hydraulic systems are complex and highly sensitive to neglect. A small oversight in maintenance can quickly lead to expensive component failure and costly downtime. This article focuses on the vital importance of hydraulic system preventive maintenance for Liebherr hydraulics. We will outline a proactive approach, emphasizing regular inspections, proper fluid and filter management, and the use of genuine Liebherr parts to significantly reduce the risk of unexpected breakdowns and ensure the longevity and reliability of your machinery.

The "Golden Rule" of Hydraulic Maintenance

The foundation of successful hydraulic system preventive maintenance is simple: clean fluid is key. Over 90% of all hydraulic system failures are attributed to hydraulic fluid contamination. Contaminants like dirt, water, and microscopic metal particles act as an abrasive, causing premature wear to pumps, motors, and seals. For Liebherr hydraulics, which are engineered to the highest standards, maintaining the quality of the hydraulic oil is the most effective way to protect your investment.

Regular Inspections and a Practical Checklist

A proactive approach begins with routine checks. A simple checklist can help operators and mechanics stay on top of the most critical aspects of Liebherr hydraulics maintenance.

Daily/Weekly Check:

-

Fluid Level and Condition: Check the hydraulic fluid level in the reservoir. A low level can cause the pump to ingest air, leading to cavitation. Also, inspect the fluid's color and clarity for signs of contamination.

-

Visual Inspection of Hoses and Connections: Look for any signs of leaks, chafing, or cracks on all hydraulic hoses and fittings. A small leak is an early warning sign of a potential major failure.

-

Listen for Unusual Noises: Pay attention to the sound of the pump. A rattling or whining noise can indicate aeration or cavitation.

Monthly/Scheduled Maintenance:

-

Changing Hydraulic Filters: The filter's job is to protect the system from contaminants. Following the recommended schedule for changing hydraulic filters is critical. In harsh, dusty environments, it is often wise to shorten these intervals. Clogged filters restrict fluid flow, which can cause overheating and stress on the Liebherr hydraulic pump.

-

System Temperature: Monitor the operating temperature. An overheating hydraulic system is a clear sign that the pump is working inefficiently, a cooler is clogged, or there is a pressure issue. This requires immediate troubleshooting.

The Significance of Quality Parts and Fluids

For all hydraulic repair and maintenance procedures, the choice of spare parts and fluids is non-negotiable.

-

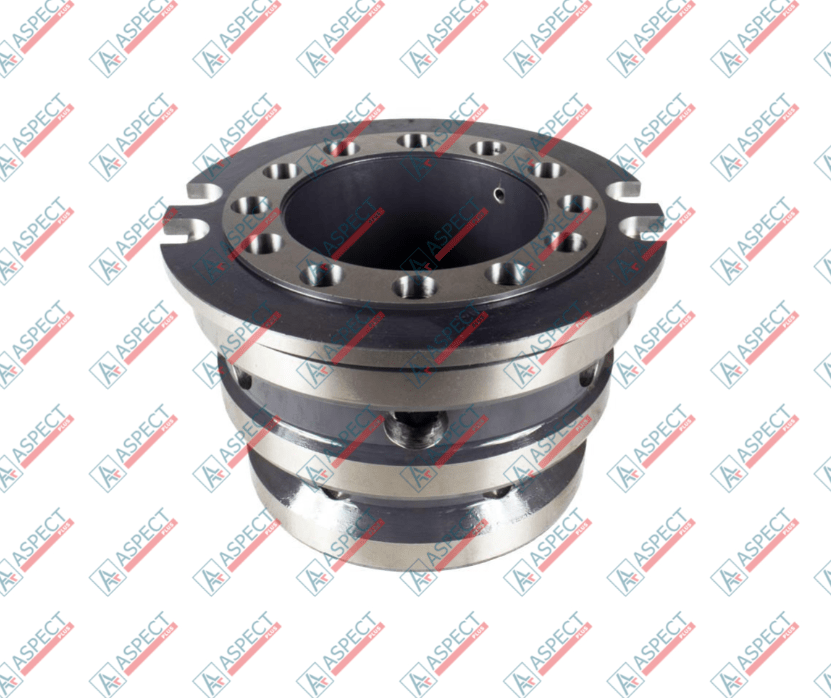

Genuine Liebherr Parts: Liebherr hydraulic pump components, cylinder seals, and valves are precision-engineered. Using genuine Liebherr parts or high-quality certified analogues ensures that the replacement component fits perfectly and is made from materials that can withstand the system's high pressures and stresses.

-

Quality Fluids: Using hydraulic oil that meets or exceeds Liebherr's specifications is vital. The right fluid provides optimal lubrication and heat transfer, directly impacting the longevity of the entire system.

Our company Aspect Plus offers a wide range of genuine Liebherr hydraulic spare parts and expert consultation to help you maintain your equipment and avoid costly downtime. We provide:

-

High-Quality Filters: To prevent hydraulic fluid contamination.

-

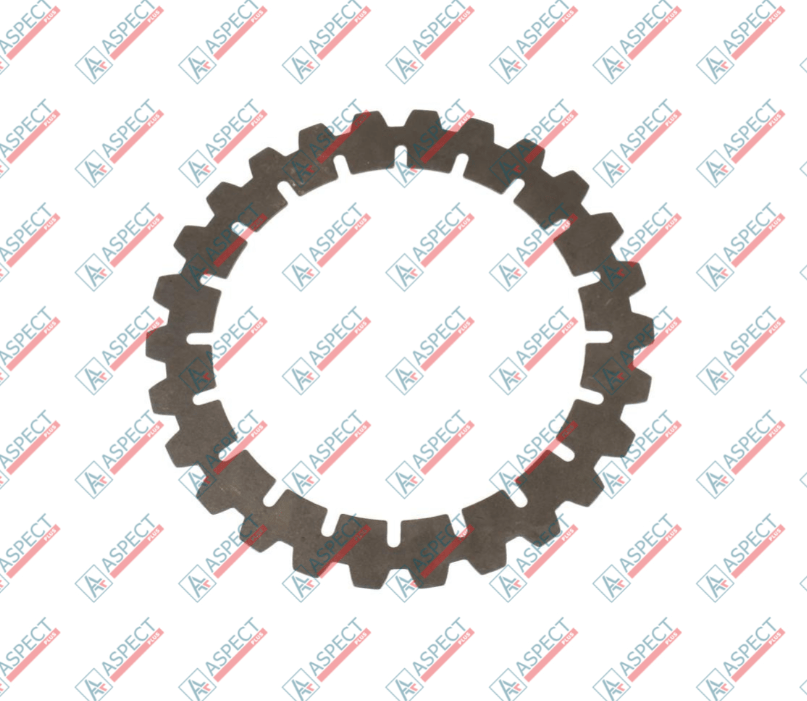

Durable Seals and Gaskets: To prevent leaks and pressure loss.

-

Genuine Pump and Motor Parts: To ensure the core of your system remains reliable.

Conclusion

Preventive maintenance of Liebherr hydraulics is the most effective strategy for ensuring the reliability, longevity, and efficiency of your excavator. By committing to a proactive approach that prioritizes clean fluid, regular inspections, and the use of genuine Liebherr parts, you can prevent common issues like pump cavitation, cylinder seal wear, and overheating. This not only minimizes the risk of unexpected failures and expensive hydraulic repair but also safeguards your investment and ensures your machinery is always ready to perform.

For professional support and a trusted source for quality spare parts for your Liebherr hydraulic system, contact the specialists at Aspect Plus. We are here to help you keep your Liebherr heavy equipment operating flawlessly.