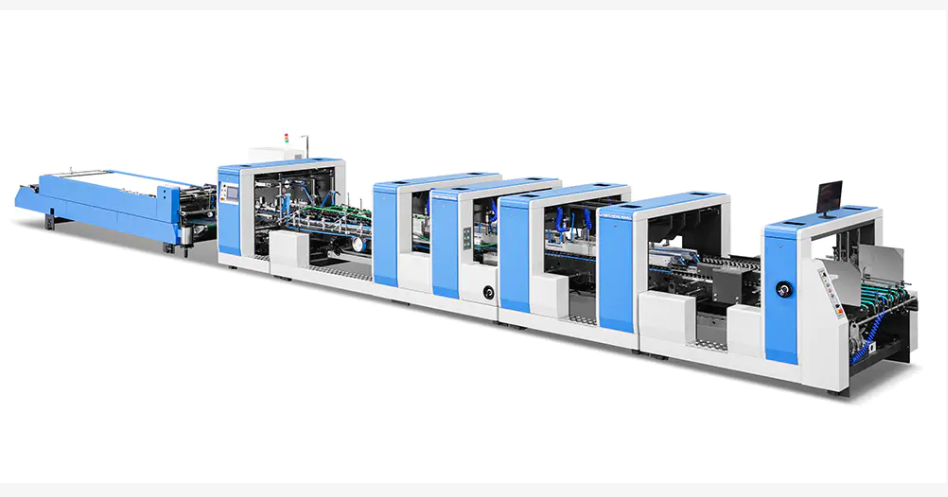

Modern packaging demands speed, precision, and structural integrity, and the Lock Bottom Folder Gluer Machine delivers all three in one compact system. By automating the intricate folds that create secure carton bases, this machine eliminates costly manual labor while boosting output. Manufacturers who adopt the Lock Bottom Folder Gluer Machine often discover that their packing lines can run at twice the previous speed without sacrificing quality. The technology behind the Lock Bottom Folder Gluer Machine centers on synchronized belts, precision gluing nozzles, and quick-change tooling that adapts to almost any carton style. Because the Lock Bottom Folder Gluer Machine can handle micro-flute, solid board, and recycled substrates, it supports sustainability goals as well as profitability.

Operators appreciate how the Lock Bottom Folder Gluer Machine reduces setup times through intuitive touch-screen controls and stored job recipes. Instead of spending half an hour adjusting rails and fold plates, a single operator recalls a saved program and watches the Lock Bottom Folder Gluer Machine calibrate itself within minutes. This flexibility makes short runs and frequent changeovers economically viable, giving brands the freedom to test seasonal graphics or limited-edition sizes without fear of downtime. The machine’s enclosed glue system also minimizes waste, ensuring that every drop of adhesive ends up on the carton rather than the floor. When maintenance is required, modular components slide out like drawers, so technicians can replace belts or nozzles without dismantling the entire Lock Bottom Folder Gluer Machine.

Quality control is another area where the Lock Bottom Folder Gluer Machine excels. Integrated vision cameras check each lock tab for proper formation, rejecting mis-folded cartons before they reach the case packer. This inline inspection capability means that customers receive flawless packages that stand up to rough handling during shipping. Furthermore, the Lock Bottom Folder Gluer Machine records production data in real time, allowing managers to track efficiency, adhesive consumption, and downtime events through a cloud-connected dashboard. Armed with this information, continuous-improvement teams can fine-tune parameters to squeeze out even greater productivity. The data also supports traceability audits demanded by food and pharmaceutical clients who rely on the Lock Bottom Folder Gluer Machine for critical secondary packaging.

From a financial standpoint, the return on investment for a Lock Bottom Folder Gluer Machine is typically realized within eighteen months, thanks to labor savings, waste reduction, and increased throughput. Contract packagers especially value the machine’s ability to switch between multiple SKUs in a single shift, enabling them to serve diverse clients without maintaining separate lines. Even smaller brands benefit, because leasing programs make the Lock Bottom Folder Gluer Machine accessible to startups that need professional-grade cartons to compete on retail shelves. Ultimately, the Lock Bottom Folder Gluer Machine is more than a piece of equipment; it is a strategic asset that future-proofs packaging operations against rising labor costs, stricter quality expectations, and ever-shorter product life cycles. By combining robust mechanics with smart digital controls, the Lock Bottom Folder Gluer Machine sets a new benchmark for what folder-gluer technology can achieve in the modern marketplace.