Introduction

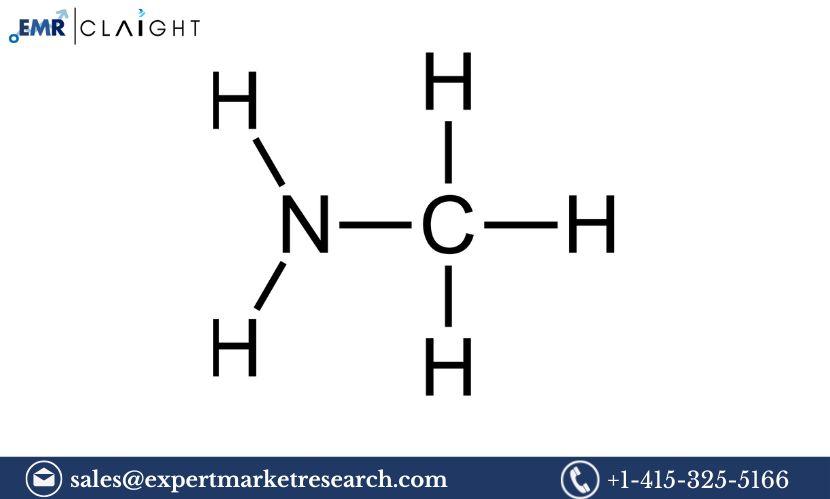

A Methylamine Manufacturing Plant Project Report outlines the steps and considerations involved in establishing a facility for producing methylamine, a vital chemical compound used in various industrial and chemical applications. Methylamine (CH₃NH₂) is a colorless, flammable gas or liquid and plays a significant role as a building block in the production of pharmaceuticals, agrochemicals, and solvents. It is an essential component in the synthesis of many important compounds, including herbicides, pesticides, and industrial chemicals.

This project report provides a comprehensive overview of the process, investment feasibility, market opportunities, and operational considerations for setting up a methylamine manufacturing plant. It will assist entrepreneurs, businesses, and investors in evaluating the potential for entering the methylamine market and ensuring the project's success.

Executive Summary

The Methylamine Manufacturing Plant will focus on the production of high-quality methylamine to serve industries such as pharmaceuticals, agriculture, and chemicals. By leveraging advanced production techniques and efficient chemical processes, the plant aims to meet the growing demand for methylamine in various sectors. The plant will use a controlled and safe production method that ensures product quality while minimizing environmental and safety risks.

Get a Free Sample Report with Table of Contents@

Key highlights of the project include:

- Production Technology: The plant will use proven technology to efficiently produce methylamine in different grades, ensuring high purity and meeting industry-specific standards.

- Diverse Market Applications: Methylamine is used in the synthesis of a wide range of chemicals, including pharmaceuticals (such as antidepressants), agrochemicals (herbicides and pesticides), and solvents in industrial applications.

- Environmental Compliance: The plant will implement measures to minimize emissions and waste by using advanced treatment and recycling systems, ensuring compliance with environmental regulations.

- Market Demand: As the demand for pharmaceuticals, agrochemicals, and specialty chemicals continues to grow, the need for methylamine is expected to rise, creating significant market opportunities.

Market Research and Feasibility Study

Market Demand

Methylamine is widely used across several high-growth industries, including chemicals, agriculture, and pharmaceuticals. The increasing demand for pharmaceuticals, the rise of modern agricultural practices, and the growing industrial need for specialty chemicals contribute to the growing demand for methylamine globally.

-

Pharmaceutical Industry: Methylamine plays an important role in the synthesis of various pharmaceutical products, including analgesics, antidepressants, and anesthetics. It is a critical component in the manufacturing of SSRIs (Selective Serotonin Reuptake Inhibitors), which are commonly used to treat conditions like depression and anxiety. The increasing global demand for pharmaceuticals, especially in developing markets, is driving the demand for methylamine.

-

Agrochemical Industry: Methylamine is used in the production of herbicides, insecticides, and fungicides. For example, it is a key ingredient in the production of glyphosate, one of the most widely used herbicides. With the growing need for efficient and sustainable agricultural practices to feed the expanding global population, the demand for agrochemicals is projected to rise, thereby driving the need for methylamine.

-

Chemical Manufacturing: Methylamine is used in the synthesis of various chemicals such as methylamine hydrochloride, methylamine sulfate, and other derivatives. These derivatives find applications in industries such as plastics, textiles, and rubber. As industrialization continues to grow globally, particularly in emerging economies, the demand for these chemicals will continue to rise.

-

Specialty Chemicals and Solvents: Methylamine is also used as a solvent in a variety of chemical processes and in the manufacture of specialty chemicals. The rise in demand for custom-made chemicals, coupled with the expansion of the chemical industry, provides a significant market opportunity for methylamine.

Competitive Landscape

The methylamine manufacturing market is competitive, with a mix of global players and regional producers. While large multinational chemical companies dominate the global methylamine market, there is room for smaller, specialized manufacturers focusing on high-purity or niche applications.

-

Key Competitors: Leading players in the methylamine manufacturing market include BASF, Dow Chemical, Celanese Corporation, and Eastman Chemical Company, which have well-established production facilities and distribution networks worldwide.

-

Opportunities for New Entrants: New entrants can carve out a niche by focusing on the production of specialized methylamine products for emerging markets or offering customized solutions for specific industries such as pharmaceuticals or agrochemicals. Additionally, new manufacturers can leverage technological innovations to improve production efficiency, reduce costs, and meet higher environmental standards.

-

Emerging Markets: Emerging markets, especially in Asia-Pacific, Latin America, and Africa, are seeing increased demand for methylamine as industries in these regions expand. These regions represent a significant growth opportunity for new manufacturers.

Regulatory Environment

Methylamine production and use are subject to various regulatory frameworks to ensure safety, health, and environmental protection.

-

Health and Safety Regulations: Methylamine is a highly flammable substance and can pose health risks if improperly handled. The plant will need to comply with strict occupational health and safety standards to minimize worker exposure and ensure the safety of personnel. This includes ensuring that proper ventilation, personal protective equipment (PPE), and safety protocols are in place.

-

Environmental Regulations: The plant will need to comply with local and international environmental regulations regarding emissions, waste management, and chemical handling. Methylamine production generates waste and emissions that must be properly treated and managed to minimize the environmental impact. Recycling solvents and incorporating energy-efficient production technologies can help reduce waste and improve sustainability.

-

Product Standards: Methylamine must meet certain purity and safety standards, especially when used in pharmaceutical and food-grade applications. The plant must ensure that its products meet the specifications required by its customers, including pharmaceutical companies, agrochemical producers, and chemical manufacturers.

Financial Feasibility

-

Capital Investment: The capital investment for establishing a methylamine manufacturing plant is significant. Key expenses include land acquisition, construction, machinery, and equipment for chemical production, as well as compliance with regulatory requirements for safety and environmental protection. The plant will also need to invest in storage facilities for raw materials and finished products, as well as transportation infrastructure.

-

Operating Costs: The primary operating costs will include raw materials (such as ammonia, methanol, and other feedstocks), energy, labor, maintenance, and waste management. Given the highly specialized nature of methylamine production, the plant will need to ensure that it maintains efficient operations to reduce production costs.

-

Revenue Generation: The plant will generate revenue through the sale of methylamine to various industries, including pharmaceuticals, agrochemicals, and chemical manufacturing. The plant can also consider diversifying its product line by producing methylamine derivatives or targeting specific high-demand sectors such as specialty chemicals and solvents.

-

Profit Margins: Methylamine production has the potential for healthy profit margins, especially if the plant can leverage economies of scale and optimize its production processes. Market demand in key sectors such as pharmaceuticals and agriculture provides opportunities for consistent revenue streams.

Manufacturing Process

The production of methylamine typically involves the following steps:

1. Raw Material Procurement

The primary raw materials for methylamine production are ammonia and methanol. These materials are readily available from natural gas processing or as by-products of other chemical processes.

2. Synthesis Reaction

Methylamine is produced through the methylation of ammonia using methanol. This reaction typically takes place under high temperature and pressure conditions in a reactor, where the ammonia and methanol react in the presence of a catalyst to form methylamine and water.

3. Separation and Purification

The methylamine product is separated from the reaction mixture through distillation or absorption. The distillation process ensures that impurities are removed, resulting in a purified methylamine product. The product is typically available in different grades depending on the application, such as industrial-grade or pharmaceutical-grade methylamine.

4. Packaging

After purification, the methylamine is packaged in appropriate containers, such as drums, bottles, or tanks, depending on the volume and customer requirements. Packaging is done with strict safety precautions to prevent leakage, as methylamine is a highly volatile and flammable substance.

5. Quality Control

Quality control is crucial to ensure that the final product meets industry standards. The plant will carry out regular testing to monitor purity levels, chemical composition, and compliance with regulatory specifications. These tests are especially important when producing methylamine for pharmaceutical or food-grade applications.

Location and Infrastructure

Selecting the right location is key to the success of the methylamine manufacturing plant. Considerations include:

-

Proximity to Raw Materials: The plant should be located near sources of ammonia and methanol to minimize transportation costs for raw materials.

-

Energy Availability: Methylamine production is energy-intensive, requiring high temperatures and pressures. The plant should be situated in an area with reliable and cost-effective energy sources.

-

Access to Transportation: The location should have good transportation links, such as highways, railways, or ports, to facilitate the movement of raw materials and finished products.

-

Environmental Considerations: The plant should be located in an area that complies with environmental regulations and has sufficient waste disposal and treatment facilities.

FAQs

1. What is methylamine used for?

Methylamine is used in the production of pharmaceuticals, agrochemicals (herbicides, insecticides), and specialty chemicals. It is also used as a solvent in industrial applications.

2. How is methylamine produced?

Methylamine is produced through the methylation of ammonia using methanol in a high-temperature and high-pressure reactor. The product is then purified and separated.

3. Is methylamine dangerous?

Methylamine is highly flammable and can be hazardous if inhaled in large quantities. Proper safety measures, including ventilation and protective equipment, are essential in handling and production.

4. What are the raw materials for methylamine production?

The primary raw materials are ammonia and methanol, which are readily available from natural gas processing or as by-products of other chemical processes.

5. What industries use methylamine?

Methylamine is primarily used in pharmaceuticals, agrochemicals, chemical manufacturing, and as a solvent in various industrial applications.

Related Reports

https://www.expertmarketresearch.com.au/reports/australia-automotive-pneumatic-actuators-market

https://www.expertmarketresearch.com.au/reports/australia-chocolate-market

https://www.expertmarketresearch.com.au/reports/australia-carbon-black-market

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au