Currently, the lithium foils used in lithium batteries on the market are generally thick, typically over 150µm, which fails to meet the increasingly stringent energy density requirements. As a key material for enhancing lithium battery performance, ultra-thin lithium foil is gradually becoming the focus of the industry. This article will delve into the current market status, processing technology, and application fields of ultra-thin lithium foil.

1. Market Status of Ultra-Thin Lithium Foil

At present, commercially available lithium foils for lithium batteries are predominantly thick, with thicknesses exceeding 150µm. This is primarily due to the softness of lithium metal, its high ductility, and relatively low compressive strength, leading to uneven thickness and large thickness tolerances. These factors directly impact the performance and energy density of lithium batteries.

As the demand for higher energy density in lithium metal batteries continues to grow, achieving ultra-thin and uniformly thick lithium foils has become critically important. Given that metallic lithium has excellent ductility, mechanical multi-stage rolling reduction processes can be employed to process it. However, the strong reducibility of metallic lithium and its high adhesion to rollers impose new requirements on environmental humidity during the thinning process and on the corrosion resistance and anti-adhesion properties of rolling equipment.

2. Processing Technology Flow for Ultra-Thin Lithium Foil

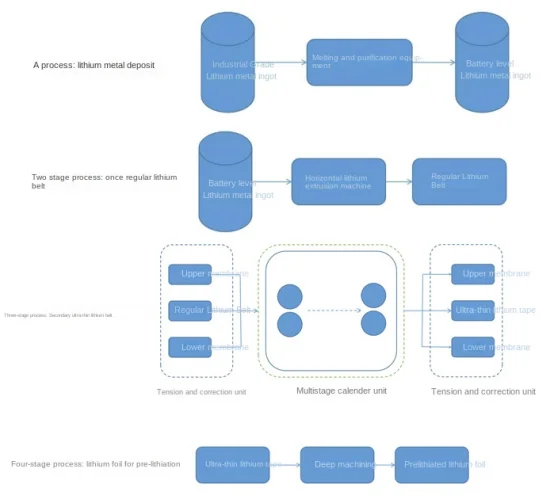

1) Stage One: Metal Lithium Extraction

Using industrial-grade lithium ingots as raw materials, impurities are removed through melting and purification equipment to obtain battery-grade lithium ingots.

2) Stage Two: Conventional Lithium Foil

Battery-grade lithium ingots are processed using horizontal extrusion machines while precisely controlling parameters to produce conventional lithium foil.

3) Stage Three: Ultra-Thin Lithium Foil

The conventional lithium foil is processed by a tension and correction unit in conjunction with upper and lower films. It undergoes multi-stage rolling reduction through rolling machines. Another set of tension and correction units adjusts the upper film, ultra-thin lithium foil, and lower film to produce ultra-thin lithium foil.

4) Stage Four: Lithium Foil for Pre-Lithiation

The ultra-thin lithium foil undergoes further processing to meet pre-lithiation requirements, enhancing the performance of lithium batteries.

3. Application Fields of Ultra-Thin Lithium Foil

Mikrouna Lithium metal extruder

1) Lithium Battery Sector

High-Performance Lithium-Ion Batteries: Used as anode materials to increase energy density and extend range in electric vehicles and portable electronic devices.

Solid-State Lithium Batteries: Reduces resistance, improves ion transport efficiency, and enhances charge-discharge performance and safety.

Lithium-Sulfur Batteries: Acts as an anode to improve energy density and cycle life, addressing long-range and high-capacity demands.

2) Electronic Device Sector

1. Micro Batteries: Used in manufacturing micro battery anodes to meet power supply needs for micro-sensors, wearable devices, and other miniaturized equipment.

2. Film Capacitors: Serves as electrode materials to enhance capacitance performance and ensure signal transmission quality in electronic devices.

3) Energy Storage Sector

1. Large-Scale Energy Storage Systems: Applied in lithium battery modules to improve energy density and charge-discharge efficiency, supporting renewable energy storage and applications.

2. Distributed Energy Storage: The produced lithium batteries can provide efficient storage solutions for home and community energy storage facilities, achieving peak shaving and valley filling.

Ultra-thin lithium foil represents a significant advancement in lithium battery technology and is one of the key factors driving the development of industries such as electric vehicles and portable electronic devices. As related technologies continue to improve, ultra-thin lithium foil is expected to deliver value across more fields, leading a new wave of technological innovation.