As the popularity of essential oils continues to rise, more people are turning to electric essential oil distillers to extract their favorite fragrances and therapeutic benefits from plants. These innovative devices simplify the distillation process, making it accessible and efficient for both hobbyists and serious enthusiasts. This article provides a detailed overview of how electric essential oil distillers work, from the basic principles of distillation to the nuances of operating the equipment.

Understanding Essential Oil Distillation

Essential oil distillation is a process designed to extract volatile compounds from plant materials, such as leaves, flowers, and stems. This is typically achieved through steam distillation, a method that uses steam to vaporize essential oils before condensing them into liquid form. Electric essential oil distillers automate much of this process, offering a convenient alternative to traditional distillation methods.

The Anatomy of an Electric Essential Oil Distiller

Before diving into the distillation process itself, it’s essential to understand the key components of an electric essential oil distiller Most units consist of several critical parts:

-

Boiler: The boiler is where water is heated to produce steam. It is an essential component that determines the efficiency of the distillation process.

-

Still Chamber: This is the chamber where plant material is placed. The steam travels through here, extracting the essential oils.

-

Condenser: After passing through the still chamber, the steam moves into the condenser, where it cools down and is converted back into liquid form.

-

Collection Vessel: This container collects the distilled liquid, which will contain both essential oils and hydrosol (the aromatic water byproduct).

-

Control Panel: Most electric distillers are equipped with a control panel that allows users to set time, temperature, and other essential parameters for the distillation process.

The Distillation Process

Now that we understand the equipment involved, let’s walk through the essential oil distillation process:

Step 1: Preparing the Plant Material

Before starting the distillation, it is crucial to prepare the plant material properly. Fresh herbs, flowers, or plant parts should be washed thoroughly to remove any dirt and pests. Cutting or crushing the plant material helps to increase surface area, allowing for more efficient steam penetration.

Step 2: Filling the Boiler and Setting Up the Distiller

Fill the boiler of the electric essential oil distiller with distilled or purified water to avoid any impurities. Most distillers specify a maximum fill line—following this guideline ensures optimal steam production. Once the water is in place, assemble the distillation unit, ensuring all connections are secure.

Step 3: Heating the Water

Next, turn on the distiller. The electric heating element heats the water in the boiler, transforming it into steam. This process typically takes just a few minutes, depending on the distillation unit’s power.

Step 4: Passing Steam Through the Plant Material

As steam is generated, it moves from the boiler through the still chamber containing the prepared plant material. The heat causes the essential oils in the plant material to evaporate and mix with the steam.

Step 5: Condensing the Steam

Once the steam has passed through the plant material, it travels to the condenser. Here, the steam is cooled down, converting it back into liquid form. The condenser's efficiency is crucial for maximizing the yield of essential oils.

Step 6: Collecting the Distillate

The liquid that collects in the collection vessel will contain both essential oils and hydrosol. Given that essential oils are lighter than water, they will float atop the hydrosol, making it easy to separate them later.

Step 7: Finishing Up

Once the distillation process is complete, the unit will typically signal that it is done. Allow the distiller to cool down before disassembling it for cleaning. Cleaning your electric essential oil distiller after each use ensures that it remains in good working condition for future distillations.

Benefits of Using Electric Essential Oil Distillers

Utilizing an electric essential oil distiller offers numerous advantages compared to traditional distillation methods:

-

Convenience: Electric distillers automate many steps in the distillation process, eliminating the need for external heat sources like stovetops or open flames.

-

Temperature Control: Most electric distillers come with precise temperature controls, allowing distillers to maintain the ideal conditions for extracting essential oils without overheating or damaging the plant material.

-

Efficiency: Electric models can distill essential oils in less time than traditional methods, making it easier to create larger amounts of oil with better yield.

-

User-Friendly Operation: With intuitive control panels and user-friendly designs, electric distillers are easier for beginners to navigate and operate.

Conclusion

Understanding how electric essential oil distillers work is key to unlocking the potential of aromatic plants and capturing the therapeutic benefits of essential oils. By employing a simple yet effective distillation process that includes warming water, creating steam, and collecting distillate, users can efficiently extract high-quality lavender oil and other essential oils.

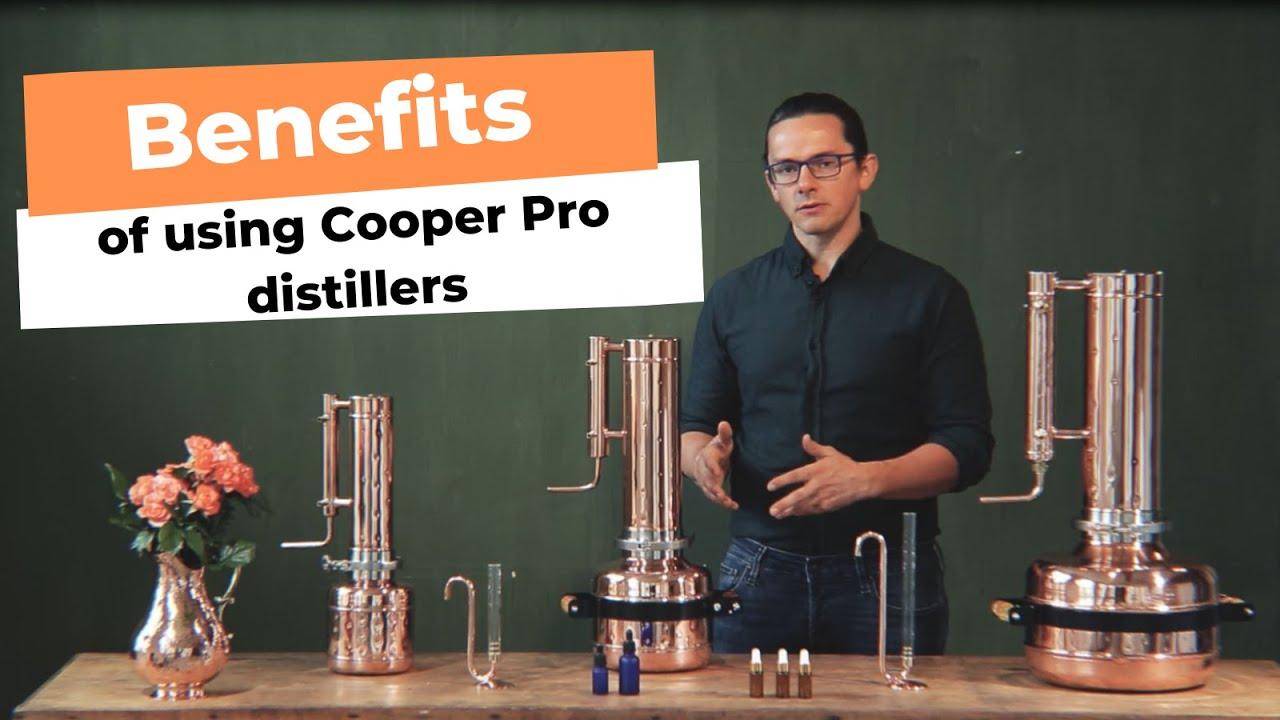

The Copper Pro company stands out in this field, offering practical aesthetic equipment that caters to various needs. From miniature desktop essential oil steam distillers to larger-scale distillation systems, Copper Pro provides solutions that empower clients to produce their own high-quality products.

Whether you are a hobbyist looking to explore the world of aromatherapy or a small business aiming to create unique blends, an electric essential oil distiller can be a valuable asset. By following the steps outlined in this article and utilizing quality equipment, you will be well on your way to enjoying the many benefits that come from distilling essential oils at home.