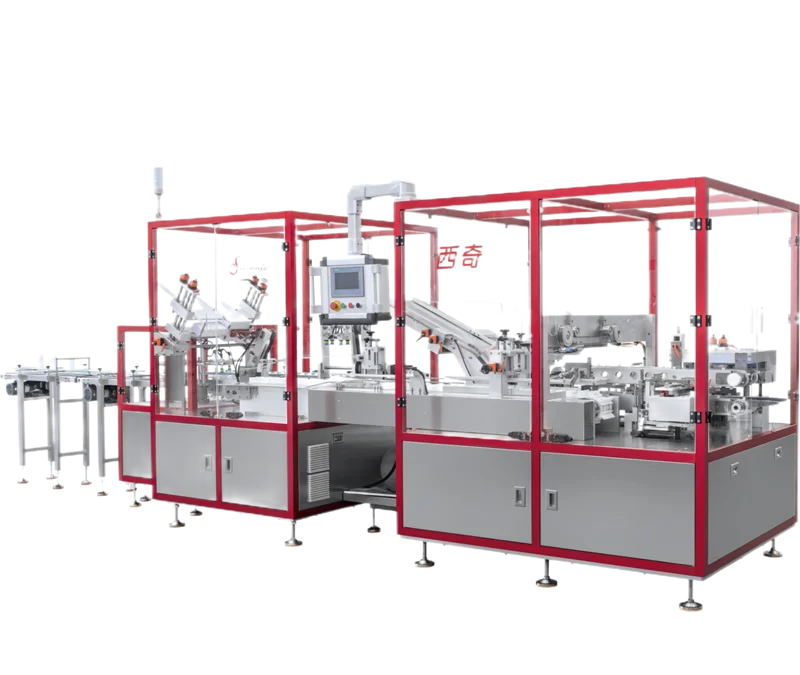

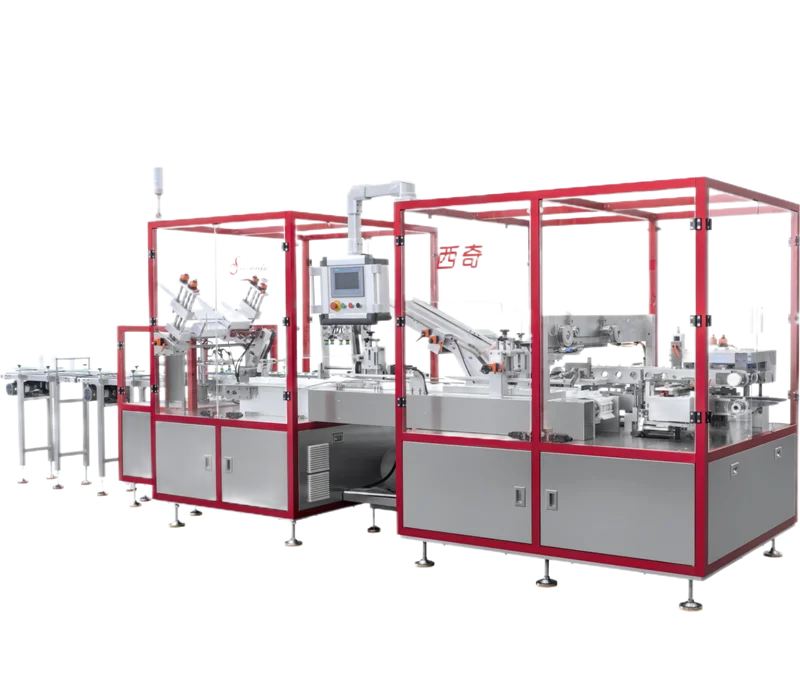

In the fast-paced world of modern manufacturing, packaging has evolved from a mere protective measure to a crucial aspect of brand identity and consumer experience. Efficient and high-quality packaging not only safeguards products during transit but also enhances shelf appeal and fosters customer loyalty. Among the myriad of packaging machinery, the SICIAUTO automatic cartoning machine stands out as a pivotal equipment piece, revolutionizing the packaging industry by significantly boosting efficiency and quality.

What is an Automatic Cartoning Machine?

An automatic cartoning machine is an advanced piece of packaging equipment designed to automate the process of placing products into cardboard cartons or boxes. This machinery integrates various functionalities, including product feeding, carton forming, product insertion, sealing, and often labeling and coding, into a seamless, automated workflow. By leveraging advanced robotics, sensors, and control systems, automatic cartoning machines ensure precision, speed, and consistency in packaging operations.

Enhancing Packaging Efficiency

1. Increased Speed and Throughput

One of the most prominent benefits of automatic cartoning machines is their ability to significantly increase production speed and throughput. Traditional manual cartoning processes are labor-intensive, prone to errors, and limit the overall capacity of packaging lines. Conversely, automatic machines can handle high volumes of products with minimal human intervention, drastically reducing cycle times and boosting daily output.

2. Reduced Labor Costs and Errors

Automation minimizes the need for manual labor, translating into substantial cost savings for businesses. By eliminating the risk of human error, such as misaligned products, incorrect carton sizes, or faulty sealing, automatic cartoning machines further enhance productivity and reduce waste. This precision also ensures that products meet stringent quality control standards, enhancing overall product integrity.

3. Flexible and Scalable Solutions

Modern automatic cartoning machines are designed with flexibility in mind. They can be easily configured to accommodate different product sizes, shapes, and packaging requirements. This adaptability allows manufacturers to streamline production lines for various product lines, reducing changeover times and optimizing resource utilization. Moreover, as business grows, automatic systems can be scaled up to meet increasing demand without compromising efficiency.

Improving Packaging Quality

1. Consistent and Reliable Packaging

Consistency is key in packaging, as it directly impacts brand image and consumer perception. Automatic cartoning machines deliver uniform results, ensuring that each carton is perfectly formed, sealed, and labeled. This consistency enhances the aesthetic appeal of the packaged products, making them more attractive to consumers and reinforcing brand standards.

2. Enhanced Product Protection

The precision of automatic cartoning machines minimizes the risk of product damage during packaging. Gentle handling mechanisms and custom-fit cartons protect fragile items from vibrations, shocks, and other transport-related hazards. This ensures that products arrive at their destination in perfect condition, preserving their value and enhancing customer satisfaction.

3. Sustainable Packaging Practices

In today’s eco-conscious market, sustainable packaging is a must. Automatic cartoning machines can be integrated with systems for using recyclable materials, minimizing waste, and optimizing carton sizes to reduce material consumption. By promoting eco-friendly practices, manufacturers can appeal to environmentally aware consumers and contribute to global sustainability efforts.

Case Studies and Real-World Applications

Numerous industries have benefited from the incorporation of automatic cartoning machines. Pharmaceutical companies, for instance, rely on these machines to ensure the sterile and secure packaging of medications. The food and beverage sector leverages automation to maintain product freshness and extend shelf life. Consumer goods manufacturers, too, have seen significant improvements in packaging efficiency and quality, enhancing their competitive edge.

Future Trends and Innovations

The future of automatic cartoning machines is bright, with ongoing advancements in technology driving innovation. Smart sensors, AI, and machine learning are being integrated into packaging systems to enhance predictive maintenance, optimize performance, and enable real-time quality control. Additionally, the development of modular and customizable machinery will further increase the versatility of these systems, catering to the diverse needs of the packaging industry.

Conclusion

Automatic cartoning machines are indispensable in today's packaging landscape, offering manufacturers a robust solution to enhance both efficiency and quality. By automating the cartoning process, businesses can significantly increase production speeds, reduce labor costs, minimize errors, and ensure consistent, reliable packaging. As technology continues to evolve, the capabilities of these machines will only grow, making them even more integral to the future of packaging and manufacturing. Embracing automation is not just a strategic move for businesses; it’s a necessity to stay competitive in an increasingly demanding market.

https://www.siciauto.com/a-key-equipment-for-improving-packaging-efficiency-and-quality.html