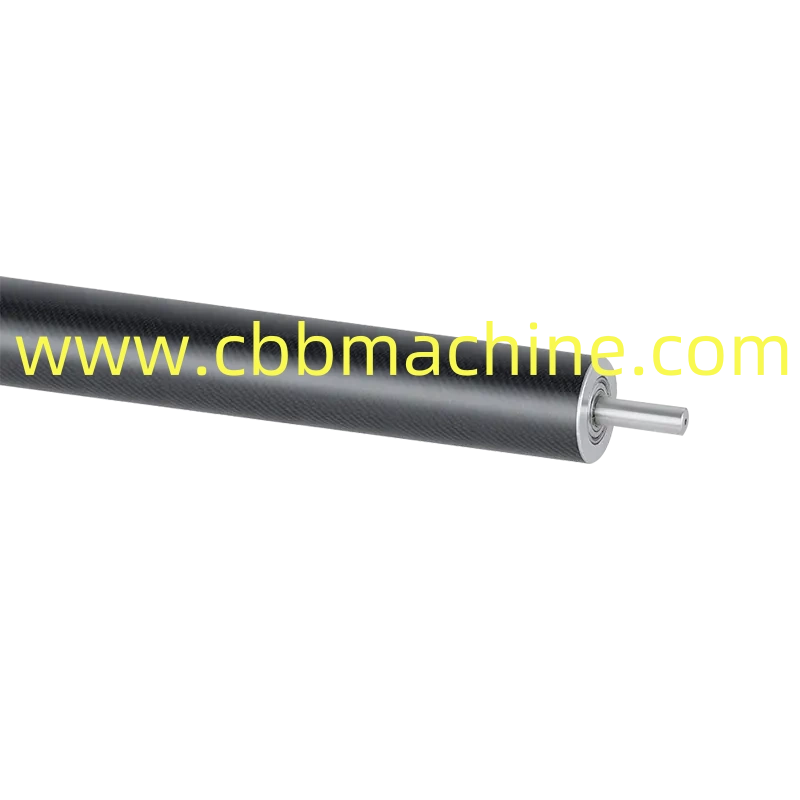

In many industrial web handling systems, precision and durability are essential, and that’s where the Aluminum Roller plays a central role in ensuring smooth and accurate material transport.

A Core Component in Modern Web Processing

Aluminum rollers are widely used in printing, laminating, slitting, coating, and packaging machinery. Their lightweight construction makes them ideal for high-speed operations where minimizing rotational inertia is critical. The use of aluminum also offers corrosion resistance, reducing the maintenance burden and extending service life—especially in environments with humidity or chemical exposure.

Engineering Advantages of Aluminum Rollers

Aluminum rollers are engineered with precision-balanced designs, allowing for superior stability and concentricity during operation. Surface treatment options such as hard anodizing or Teflon coating improve wear resistance and reduce friction. These features are vital for maintaining consistent web tension and alignment, which directly impact product quality and production efficiency.

Additionally, aluminum allows for quicker heat dissipation compared to steel, making these rollers suitable for processes where thermal control is necessary, such as film stretching or heat-sensitive material handling.

Customization and Versatility

One of the key strengths of aluminum rollers lies in their adaptability. They can be produced in various diameters, lengths, and groove patterns depending on the material and process requirements. From guiding ultra-thin films to handling thick paper rolls, aluminum rollers offer customization to suit nearly any web application.

Moreover, with options like static elimination systems, grooved surfaces for airflow, or knurled textures for grip, manufacturers can further optimize performance based on the nature of the web and machinery setup.

Application Fields and Reliability

Industries relying on continuous web production—such as printing, battery film production, nonwovens, and flexible packaging—trust aluminum rollers for their precision, strength-to-weight ratio, and operational consistency. Whether integrated into simple unwind systems or complex, multi-stage production lines, aluminum rollers provide the consistency and reliability required for uninterrupted productivity.

For companies that prioritize machine performance, investing in high-quality aluminum rollers is a step toward minimizing downtime and maximizing throughput.

To explore premium-grade options that meet your production needs, visit https://www.cbbmachine.com/product/aluminum-roller/