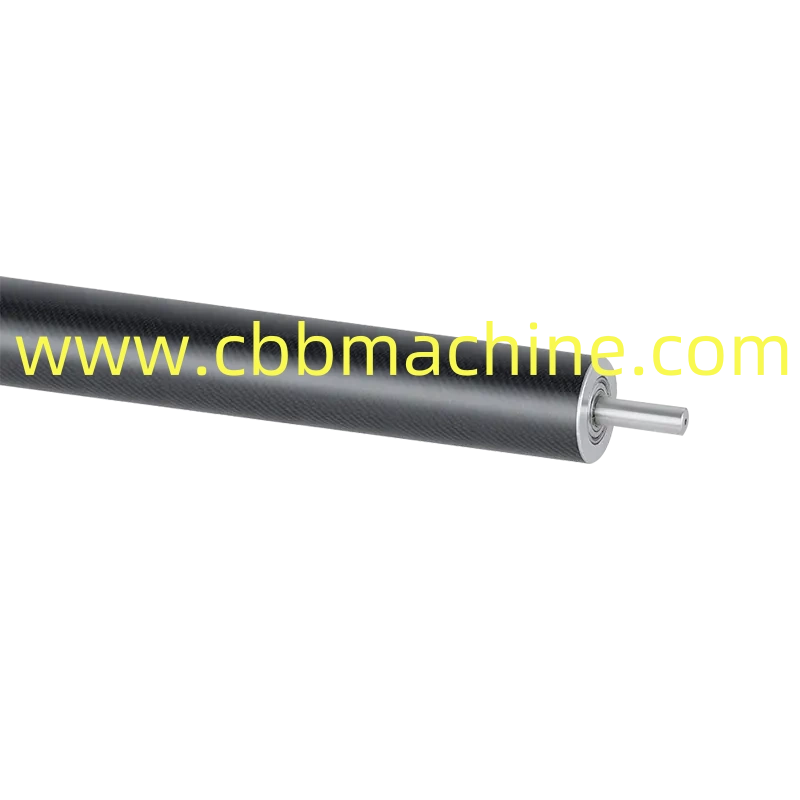

In precision machinery systems, an Aluminum Roller often sits at the heart of smooth material transportation and tension control across high-speed processing lines.

Understanding the Importance of Aluminum Rollers

Aluminum rollers play a fundamental role in web handling, where materials such as plastic films, textiles, paper, or foil are continuously transported, stretched, printed, or laminated. Thanks to their lightweight construction, excellent heat dissipation, and corrosion resistance, these rollers have become indispensable in converting and packaging industries.

What sets aluminum rollers apart is their strength-to-weight ratio. Compared to steel, aluminum allows for faster response and acceleration in fast-moving lines while reducing the overall load on the machinery. This translates to increased energy efficiency and reduced wear on drive components such as motors and bearings.

Applications Across Diverse Manufacturing Fields

Aluminum rollers are used in many sectors, including flexible packaging, lithium battery production, textile finishing, paper processing, and film extrusion. Their versatility is largely due to the surface finish and customizable design options available.

For example, a roller used in high-temperature drying sections may require an anodized or ceramic-coated surface to withstand heat. In contrast, rollers used for plastic films benefit from polished or hard-coated surfaces to prevent scratches and static buildup. These configurations ensure product safety, consistency, and improved output.

Benefits of Precision Manufacturing

Quality aluminum rollers are precision-balanced to minimize vibration at high speeds. This is crucial in industries like electronics and packaging, where even slight surface deviations can lead to product defects or misalignment. Advanced manufacturing techniques, such as CNC turning and dynamic balancing, ensure consistent roundness and concentricity across the roller’s surface.

Hollow or solid shafts, different core diameters, and mounting options can all be tailored to specific applications. Anti-static brushes, rubber coatings, or grooves can also be added based on customer requirements.

Maintenance and Long-Term Performance

Despite their lightweight nature, aluminum rollers are highly durable. When maintained properly, they provide long service life even under challenging operational conditions. Their corrosion-resistant properties make them especially suitable for humid or chemical-laden environments, reducing the need for frequent replacements or costly repairs.

Simple maintenance routines—such as cleaning buildup, inspecting shaft integrity, and monitoring bearing condition—can keep these rollers functioning optimally for years. Moreover, their compatibility with a wide range of support systems ensures easy integration into existing production lines.

To learn more about custom options, finishes, and technical specifications, visit https://www.cbbmachine.com/product/aluminum-roller/