In modern manufacturing industries, effective web handling plays a crucial role in ensuring smooth production processes. One essential component designed to improve tension control and material alignment is the innovative Banana Rollers , which help in evenly distributing tension across flexible materials like films, textiles, and paper during processing. Their unique curved shape allows materials to stay centered on the rollers, preventing wrinkles and misalignment that can cause defects or machine downtime.

These rollers are highly customizable to meet specific industrial needs. Manufacturers can adjust the roller's curvature, size, and surface finish to suit different material types and production speeds. This flexibility means they can be integrated into various machines, including printing presses, packaging lines, and converting equipment, enhancing overall efficiency. The ability to tailor roller characteristics ensures consistent product quality and minimizes material waste.

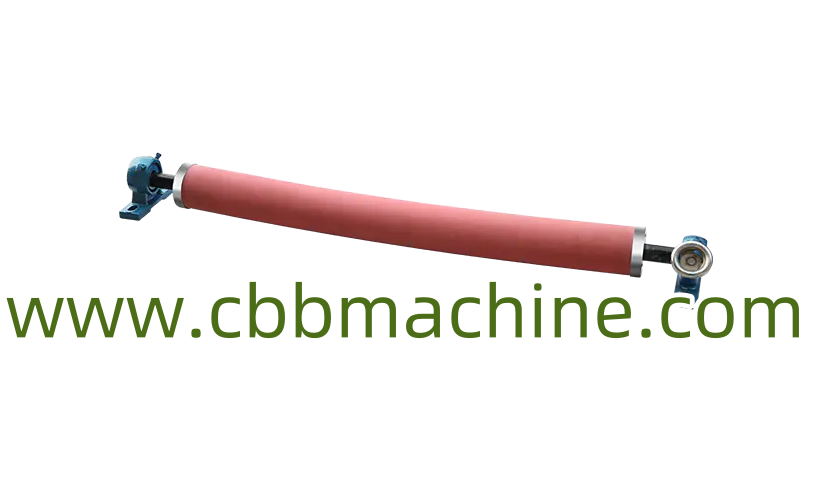

Durability is another important feature of these rollers. They are often made from high-quality materials such as stainless steel, polyurethane, or rubber coatings, which resist wear and corrosion even under harsh environmental conditions. This ensures longevity and reduces maintenance frequency, saving time and costs for production facilities.

Energy efficiency also benefits from the use of curved rollers. By maintaining proper web tension and alignment, they reduce unnecessary strain on motors and other components, resulting in lower energy consumption and smoother machine operation. This aspect is especially valuable for factories aiming to reduce their carbon footprint while optimizing productivity.

In addition to performance improvements, these rollers contribute to safety. By preventing material slips and jams, they help avoid sudden machine stops or accidents, protecting workers and machinery. Many models also feature easy installation and adjustment mechanisms, allowing operators to fine-tune tension settings without extensive downtime.

Industries such as packaging, textile, paper, and plastic film production widely adopt this technology because it enhances both speed and precision. By reducing defects caused by tension inconsistencies or misalignment, the rollers increase throughput and lower costs associated with waste and rework. This makes them a strategic investment for manufacturers looking to stay competitive.

When selecting the right curved roller, it is important to consult with experienced suppliers who offer customization options and technical support. This ensures the product fits seamlessly with existing equipment and meets production goals effectively.

Overall, using advanced curved rollers designed specifically for web handling significantly boosts manufacturing efficiency and product quality. Their customizable nature, durability, and contribution to energy savings make them indispensable components in modern industrial settings.

For more information about customizable rollers tailored to your needs, visit https://www.cbbmachine.com/product/banana-roller/customizable-banana-roller.html