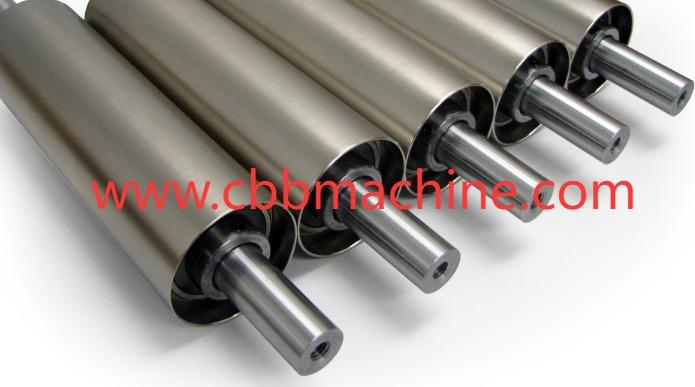

In high-precision production lines, efficient material guidance and surface handling are essential. The Aluminum Roller developed by Cbbmachine meets this demand with a focus on dimensional accuracy, surface smoothness, and structural durability—attributes vital for maintaining tension and stability in continuous processes.

Crafted from lightweight yet robust aluminum alloy, these rollers are designed to support a wide range of industrial applications, from film processing and paper converting to textile coating and flexible packaging. Their consistent performance helps reduce vibration, minimize product deviation, and ensure smooth material flow even at high operating speeds.

The non-corrosive properties of aluminum make these rollers especially suitable for environments exposed to humidity, chemicals, or fluctuating temperatures. Their thermal conductivity supports applications requiring heat dissipation, while the low mass contributes to energy-efficient operation, particularly in fast-moving systems.

Surface treatments such as anodizing, polishing, or hard coating further extend the roller's life cycle and functional range. These options allow for improved wear resistance, reduced friction, and compatibility with specialty materials, ensuring clean contact and preserving product quality during processing.

Whether integrated into a new build or replacing a worn component, the adaptability of the aluminum roller format enables custom sizing, grooving, or balance tuning to fit specific machinery requirements. This flexibility makes them a valuable asset in both automated lines and semi-manual setups.

From printing and laminating to slitting and rewinding, aluminum rollers play a subtle yet critical role in achieving consistent, controlled output. Their design focuses not only on form but also on how each rotation supports production accuracy and operational continuity.

Curious how these rollers can align with your machinery goals? Visit https://www.cbbmachine.com/ and explore how every aluminum cylinder is more than just a part—it's a step toward process confidence, engineered for your pace.