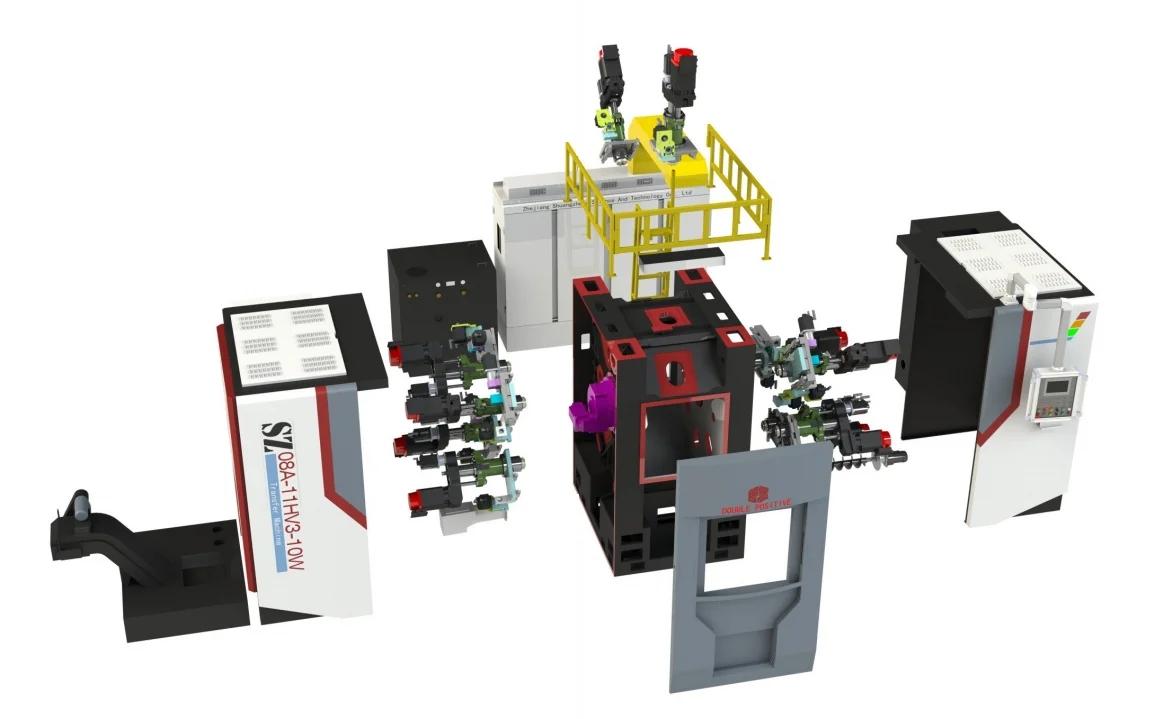

As a high speed, high precision and high reliability equipment, transfer machine is mainly used for the processing of precision and complex rotary parts. It can meet the processing of inner and outer circle, step surface, cone surface, spherical surface, groove, pick thread and complex surface. It can meet the rough and fine processing of copper, aluminum, iron, stainless steel and other casting and forging parts.

The transfer machine adopts 30° sliding saddle, adopts completely closed protection, does not leak oil, environmental protection and beautiful. In the hot summer, our practice found that the deformation of the machine tool after heating is an important reason for affecting the processing accuracy. The machine tool is affected by the change of ambient temperature in the workshop, motor heating and mechanical friction heating, cutting heat and cooling medium, resulting in uneven temperature rise of each part of the machine tool, resulting in changes in the shape accuracy and processing accuracy of the machine tool. The surrounding environment of the machine tool refers to the thermal environment formed by various layouts in the close range of the machine tool. They include the following three aspects.

(1) Workshop microclimate: such as the distribution of temperature in the workshop (vertical direction, horizontal direction). When day and night alternate or climate and ventilation change, the workshop temperature will change slowly.

(2) Workshop heat source: such as solar irradiation, heating equipment and high-power lighting radiation, they can directly affect the temperature rise of the whole or some parts of the machine tool for a long time when they are close to the machine. The heat generated by adjacent equipment during operation will affect the temperature rise of the machine in the form of radiation or air flow.

(3) Heat dissipation: the foundation has a good heat dissipation effect, especially the foundation of precision machine tools should not be close to the underground heating pipeline, once the leak is broken, it may become a heat source that is difficult to find the cause; The open workshop will be a good "radiator", which is conducive to the temperature balance of the workshop.

(4) Constant temperature: The workshop adopts constant temperature facilities for precision machine tools to maintain accuracy and processing accuracy is very effective, but the energy consumption is large.

transfer machine https://www.zjshuangzheng.com/Integrated-Transfer-Machine.html