In the mountain-ringed republics of Central Asia, earthquake risk is not an abstract concept but a daily reality. From Almaty to Dushanbe, new schools and trauma centers are being designed with one component that engineers refuse to omit: the Linear Base Seismic Isolation Rubber Bearing. By placing these bearings between the foundation and the super-structure, designers create a flexible layer that can absorb lateral energy before it reaches the columns. Recent calculations carried out for a 300-bed regional hospital in southern Kyrgyzstan show that the introduction of Linear Base Seismic Isolation Rubber Bearing reduced the peak floor acceleration from 0.45 g to 0.11 g, a drop that protects both life-saving equipment and the lives of patients.

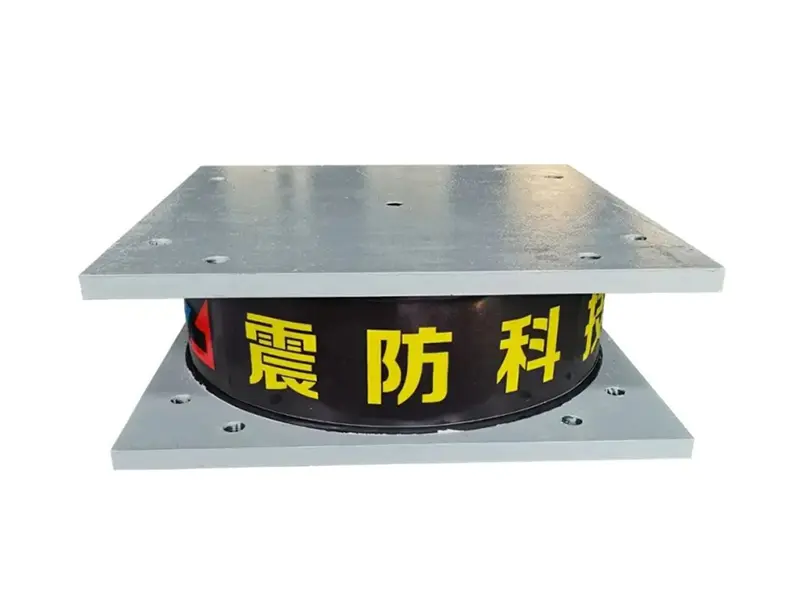

For education authorities the decision is equally urgent. After the 2011–2012 seismic swarms along the Talas-Fergana fault, the Ministry of Emergency Situations of Uzbekistan made it mandatory that any new school above two storeys must incorporate Linear Base Seismic Isolation Rubber Bearing or an equivalent system. Engineers explain that the Linear Base Seismic Isolation Rubber Bearing is not simply an extra pad; it is a precisely engineered stack of natural rubber sheets and steel shims vulcanised together to give a known, linear shear stiffness. This linearity allows the bearing to return the structure to its original position after an earthquake, eliminating costly post-event realignment.

Cost remains the most frequent objection raised by provincial governors. Yet a recent life-cycle analysis financed by the World Bank demonstrates that using Linear Base Seismic Isolation Rubber Bearing adds only 4 % to the upfront budget of a typical four-storey school in Tajikistan, while cutting expected repair costs after a moderate quake by more than 60 %. The same study notes that local precast plants in the Sughd region have already begun moulding the rubber-steel laminates under a technology-transfer agreement with Korean suppliers, bringing the unit price of Linear Base Seismic Isolation Rubber Bearing down by 18 % in just two years.

Maintenance is another concern voiced by facility managers who remember the cracked neoprene pads of Soviet-era bridges. The modern Linear Base Seismic Isolation Rubber Bearing, however, is protected by an outer rubber cover compounded to resist ozone, UV radiation and the −30 °C cold snaps common on the steppe. On-site inspectors need only a simple ruler and a durometer to verify that the bearing remains within tolerance, making the Linear Base Seismic Isolation Rubber Bearing one of the few seismic devices that can be checked without heavy equipment.

Linear Base Seismic Isolation Rubber Bearing: A Lifeline for Schools and Hospitals in Central Asia

Record

Recording 00:00

Commenting has been turned off for this post.

Categories

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Did Sean McVay slip up by maintaining special teams coach?

Los Angeles Rams head train Sean McVay announced earlier today adhering to completion of the...

Gaspar Construction: Your Trusted General Contractor for Custom Homes

Building a new home is an exciting journey, but it can also feel overwhelming. The vision...

Diamond Dreams – Ideal Franchises for Aspiring Shortstops in MLB The Show 25

Choosing the ideal team to begin your shortstop career in MLB The Show 25 is about more than logo...

[ NEW VIRAL!]] Sophie Rain SpiderMan -Leaked Video tutorial Original full videos Clip ljk

CLICK THIS L!NKK 🔴📱👉...