A Plastic Cap Mold is the silent architect behind every bottle top in your refrigerator. From carbonated soft drinks to pharmaceutical syrups, the Plastic Cap Mold shapes molten resin into threaded closures at blistering speed. Designers begin by analyzing bottle neck finish standards—PCO 1881, 1810, or 38 mm—to ensure that each Plastic Cap Mold produces caps that grip, vent, and tamper-evidently seal. Once geometry is locked, CAD models flow into CAM software that programs five-axis CNC mills. Hardened tool steel such as H13 or S136 is rough-milled, heat-treated to 48–52 HRC, and then finish-ground to tolerances within 0.01 mm. Every cavity insert within a Plastic Cap Mold must duplicate the next so that one hundred caps are interchangeable.

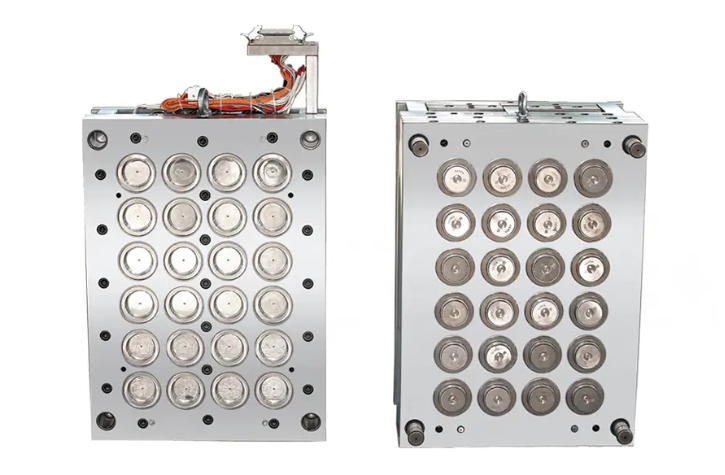

Hot-runner manifolds sit at the heart of a modern Plastic Cap Mold, keeping PET, HDPE, or PP in a molten state until it reaches the gate. Valve-gate sequencing prevents unsightly vestige while balancing fill pressure across thirty-two or even ninety-six cavities. Cooling circuits snake conformally around the cores; turbulent water flow extracts heat so that a Plastic Cap Mold can spit out a cap every 2.8 seconds. Intermittently, cavity pressure and temperature sensors stream live data to the injection machine, allowing closed-loop process control. If a spike signals a short shot, the Plastic Cap Mold automatically diverts the suspect part into a reject bin.

Ejection begins when stripper rings travel upward, pushing caps off unscrewing cores driven by hydraulic motors. Thread unscrewing must be synchronized to 0.1 degrees; otherwise, oval caps will jam capping machines downstream. After ejection, robotic arms place the still-warm caps on chillers that freeze the final dimensions. A quality lab then audits ten caps per hour, measuring thread pitch, top-load strength, and tamper-band bridge break force. Any deviation triggers a root-cause review in which technicians inspect every gate, vent, and ejector pin inside the Plastic Cap Mold.

Preventive maintenance keeps a Plastic Cap Mold profitable. After every five million cycles, operators disassemble the tool, ultrasonic-clean hot-runner tips, replace O-rings, and polish cavity surfaces with diamond paste. Laser-welding repairs nicks, while TiCN coatings extend abrasive wear life by 30 %. Simulation software is re-run annually to verify that evolving resin grades have not altered shear heating profiles. Ultimately, a well-engineered Plastic Cap Mold is not just steel and circuitry; it is a living document of continuous improvement, translating grams of plastic into billions of secure closures that travel from filling line to consumer pantry every single day. Reputable mold builders document every change order so that when a beverage brand requests a lighter 28 mm cap, the next Plastic Cap Mold iteration meets the challenge without reinventing the wheel.

Because sustainability now drives purchasing decisions, new Plastic Cap Mold designs integrate lightweighting algorithms. Finite-element analysis subtracts 0.2 g of resin while retaining top-load targets. Recycled-content PP flows differently, so rheological tweaks inside the runner system compensate for higher melt viscosity. In short, the Plastic Cap Mold is both a manufacturing marvel and an environmental steward, proving that precision and planet can share the same blueprint.