PP woven fabric has become the material of the future in a case where strength, longevity and sustainability are highly regarded values. Besides its robust nature, lightweight and sustainability, the fabric is changing the packaging and transportation of products all over the world. It is widely employed by pp fabric manufacturers to create various types of products that satisfy the most stringent requirements of the agricultural, construction, logistics and retail sectors. Its durability and cost-effectiveness are unmatched, no matter whether it is a roll of pp woven fabric or woven sack-converted material. Reliable suppliers and innovative manufacturers are reshaping industries and establishing the latter as the ones critical for ensuring permanence in quality and supply during their evolution.

The Manufacturing Process and Key Properties

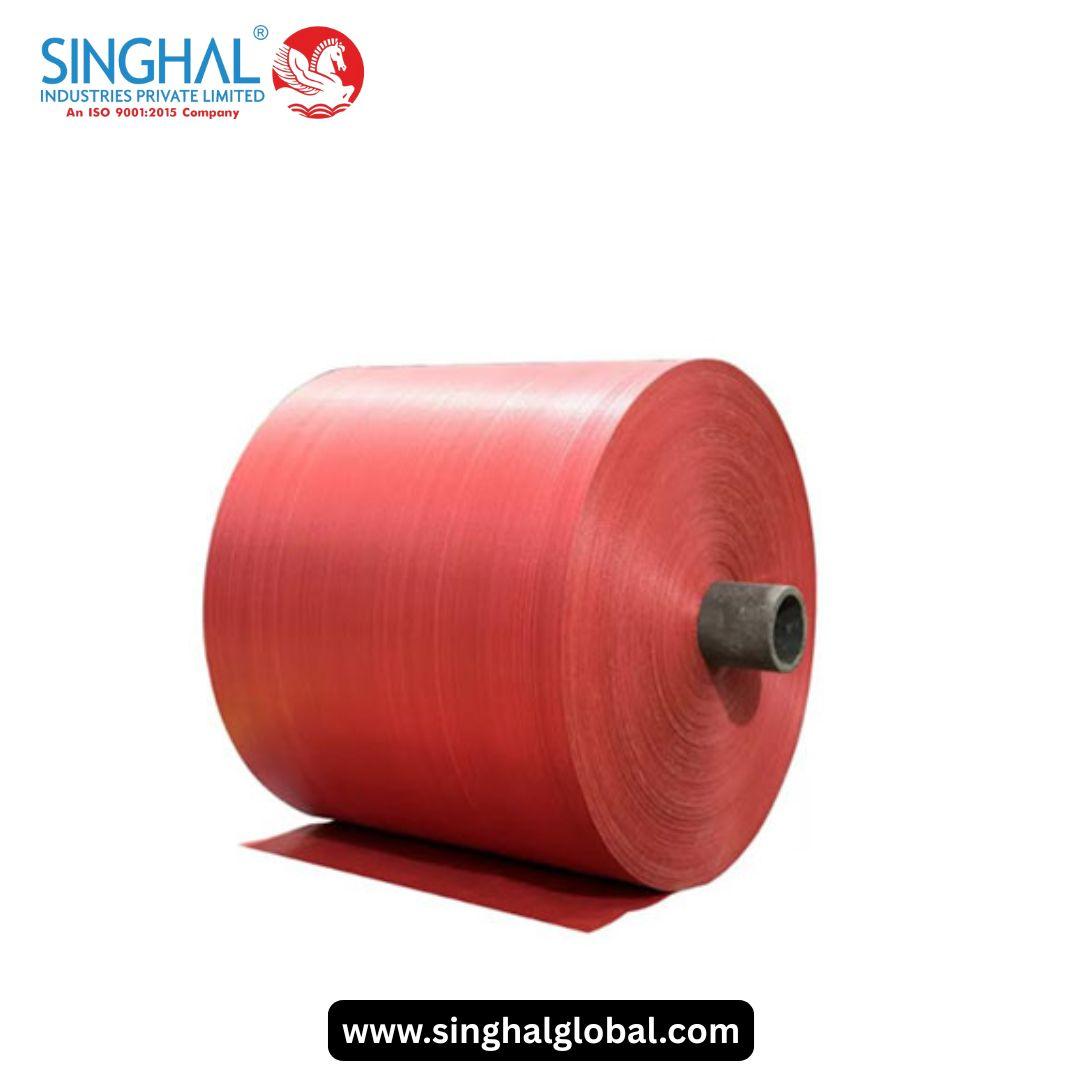

The production of PP woven sacks manufacturers in india involves a complicated weaving process, which starts with the extrusion of polypropylene fibers, followed by weaving to create a thick and sturdy fabric sheet. The manufacturers enjoy the freedom to adjust the fabric thickness, strength, color, and finish by varying the weaving parameters, thus matching the product requirements exactly. Top-level equipments ensure that the fabric is of the highest quality and can largely be used in heavy-duty projects. Normal fabric is already water-resistant to a certain degree, but if rubberized, it becomes totally impervious to water. In addition, the lightness of PP woven fabric contributes largely to transportation cost savings, and its recyclability rates are on a par with the global environmental goals. The multi-faceted pp woven fabric roll also permits customer-initiated processes like coating and lamination, which are recognizable in multiple use sectors.

Advantages That Make PP Woven Fabric Stand Out

The growing demand for the pp woven fabric is mainly attributed to its long list of benefits. One of which is the material being strong enough to carry large volumes of items such as cement, fertilizers, grains, and textiles without bursting, to name a few practice applications. Furthermore, its protection against water and chemicals makes the takeover inside the bags remain dry and chemically safe, even in the case of bad weather. Another feature of this product is the UV resistance, which prolongs the fabric's life and hence it is suitable for outdoor use. Besides, its earth-friendly nature, being recyclable and mostly made from recycled polypropylene, is increasingly picked up by the industry players as well as the consumers. Together they help make India pp woven sacks manufacturers as well as their global counterparts turn to this fabric for the production of dependable and ecological packaging solutions.

Diverse Applications in Different Industries

One of the reasons for PP woven fabric roll to be transformed into various types of products is its flexibility or better still its versatility. Any roll of pp woven fabric can be converted into various products, such as, these rolls can be cut, sewn and customized to make sacks, bags, liners, front and back protectors. India is one of pp woven sacks manufacturers who utilize this fabric to produce sacks for cement, fertilizers, grains, and animal feed--products that need to be strong enough to resist the impact of the rough handling and variations of the climate. The fabric also can be found in the production of agricultural covers, geotextiles for stabilizing soil, construction barriers as well as automotive and furniture industries. Basically, the fabric has become the leading choice by these industries because of the proved features of the fabric and the ability of the fabric to be customized that is one of the reasons why the fabric is broadly utilized by the market thus resulting in a continuous increase of its user market.

Sustainability and Future Trends

Concern for the environment lead to the continuous innovation of the industry. The main features of PP woven fabric that are in support of sustainability are its recyclability and the production of recycled polypropylene-based products. Manufacturers are implementing various types of green measures which include the use of biodegradable coatings and waste reduction techniques. Not only the excellence in the aesthetic aspect of the fabric but also the functional properties that result from technology integration like digital printing and advanced coating procedures, make the way for branding and product differentiation. In the future, first, theme of the biodegradable PP woven fabric along with smart fabric equipped with sensors and more environmentally friendly production methods will be implemented which, upon the users' acceptance, will guarantee the longevity of this fabric in the upcoming decades, ensuring that it remains eco-friendly.

Conclusion

By the use of PP fabric manufacturer, initially being made of recyclable materials, the performance, and life of the product have been improved significantly, resulting in the material being a strongly preferred solution across various sectors. Its ability to be converted into different products—especially as a pp woven fabric roll or pp woven sacks—makes it a material not only for packaging but also for agriculture and construction. The products thus play an important role in the transition to greener industrial practices as their properties and applications will broaden further with innovation from pp fabric manufacturers. Companies looking for high-quality and trustworthy solutions will find it very beneficial to be working alongside Indian pp woven sacks manufacturers and other global suppliers. This eco-friendly and stable product can easily meet the changing demands of the market while being a very important part of sustainable industrial growth.

Frequently Asked Questions (FAQs)

-

What is PP woven fabric, and what are its primary uses?

It is a durable, light fabric which is the product of the weaving of polypropylene fibers. Mainly, it is given to the above-mentioned materials like sacks, bags, geotextiles. -

How is PP woven fabric manufactured?

It is a procedure of melting the polypropylene into tiny filaments, weaving these filaments into fabric sheets, and adding the finishing touches like the coatings for the enhanced properties. -

What makes PP woven fabric so durable?

Its strength at the limit of breakage, resistance to injury, water, chemicals and anti-UV rays protectiveness greatly contribute to its durability. -

Can PP woven fabric be customized?

Of course, such as the fabric can go through processes like coating, lamination, printing or sewing for the exclusive requirements of the industry. -

Where can I buy a PP woven fabric roll?

The leading producers and distributors, especially those who are engaged in industrial textiles, are the ones who supply the high-quality fabric rolls. -

Who is the largest supplier of PP Woven Fabric?

Singhal Global PVT Ltd is a supplier of PP Woven Fabric, but not necessarily and the largest in the world. The largest supplier of PP Woven Fabric varies based on region and demand on the market. -

Who is the largest exporter of PP Woven Fabric?

Singhal Global PVT Ltd may be a recognized exporter of PP Woven Fabric, but it is not typically identified as the largest exporter worldwide. -

Who is the largest manufacturers of PP Woven Fabric?

Singhal Global PVT Ltd is one of the manufacturers of PP Woven Fabric, but it is not generally recognized as the largest manufacturer worldwide. -

What is the typical lifespan of PP woven sacks?

If they are used properly, they can still be effective for a couple of years, to a certain extent, in outdoor or industrial areas. -

What are the future developments expected in PP woven fabric technology?

Some of the developments that the industry is predicting include biodegradable fabrics, the use of sensors for smart textiles, and production that is eco-friendly.