In the world of precision machinery and web handling systems, the Aluminum Roller remains a fundamental component due to its lightweight structure, excellent corrosion resistance, and superior thermal conductivity. Found in a wide range of industrial machines, these rollers play a crucial role in supporting, guiding, and transporting web materials such as films, papers, foils, and textiles throughout production processes.

What makes aluminum rollers stand out is their combination of strength and low weight. Unlike steel rollers, which can add significant mass to rotating equipment, aluminum rollers reduce the load on the machine’s drive system. This directly contributes to energy efficiency, easier installation, and lower wear on bearings and shafts. As a result, machines that utilize aluminum rollers can operate at higher speeds with reduced power consumption and extended service life.

Aluminum as a material offers another key advantage—its natural resistance to corrosion. In environments where humidity, temperature fluctuation, or chemical exposure are factors, aluminum rollers maintain their structural integrity far better than some other metals. This makes them ideal for use in printing, packaging, laminating, and textile applications, especially where moisture or solvents are involved.

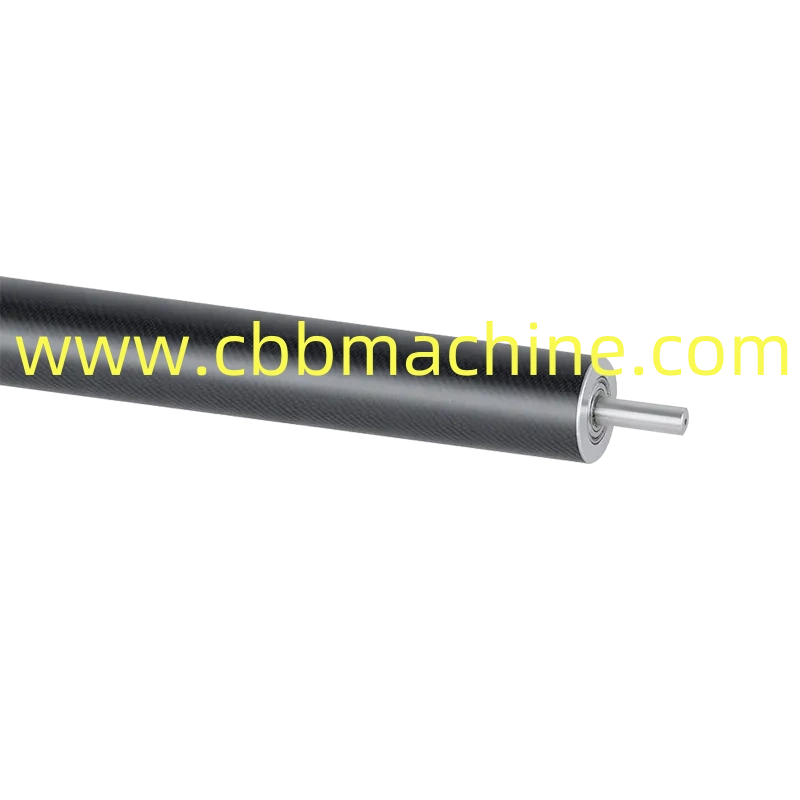

CBBMachine specializes in manufacturing precision-engineered aluminum rollers that can be tailored to suit specific application needs. From surface treatments like hard anodizing or Teflon coating to customized diameters, wall thicknesses, and shaft interfaces, each roller can be optimized for functionality and durability. This ensures smooth rotation, minimal vibration, and effective material handling even under high-speed or high-tension conditions.

One often overlooked aspect of aluminum rollers is their ability to dissipate heat efficiently. This is particularly beneficial in processes involving heated webs or friction, such as laminating and thermal bonding. The roller’s surface can be machined to various finishes—polished, grooved, or knurled—to further improve traction, web alignment, and cleanliness.

In addition, aluminum rollers require less maintenance due to their resistance to oxidation and material buildup. Their lighter weight also makes handling and replacement much easier for technicians, reducing downtime during routine maintenance or system upgrades.

When selecting rollers for industrial machinery, factors like weight, load capacity, precision balance, and environmental resistance must be carefully considered. With the ability to meet all these criteria, aluminum rollers provide a reliable and cost-effective solution. Whether used as idler rollers, guide rollers, or driven rollers, they support production lines by ensuring accurate and efficient material transport.

For detailed product information and customization options, visit:https://www.cbbmachine.com/product/aluminum-roller/