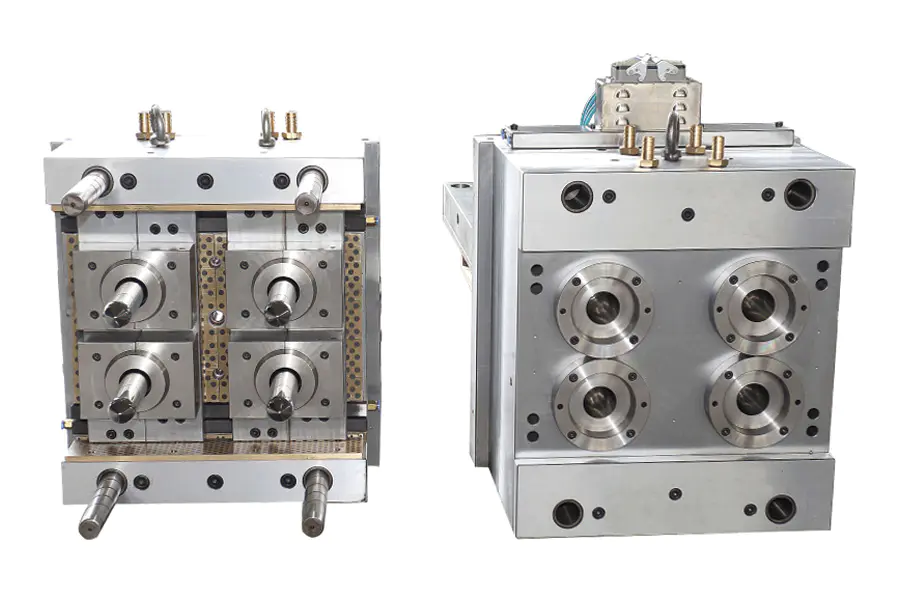

The 4 Cavity 3-Gallon Preform Mold has become the benchmark for medium-volume PET packaging lines that need both speed and dimensional accuracy. By shaping four 3-gallon preforms in every 35-second cycle, the 4 Cavity 3-Gallon Preform Mold quadruples output without enlarging the press footprint. Tool-grade 2316 stainless steel, hardened to 45-48 HRC, gives the 4 Cavity 3-Gallon Preform Mold abrasion resistance for more than one million shots, while a balanced hot-runner system keeps melt flow identical across all four cavities.

Water-cooled neck rings and core rods extract heat quickly, so the 4 Cavity 3-Gallon Preform Mold can run at lower injection pressures, saving up to 12 % energy versus single-cavity tools. Interchangeable cavity inserts allow the 4 Cavity 3-Gallon Preform Mold to switch between 300 g and 520 g preforms in under twenty minutes, giving converters the flexibility to serve both light-weight and heavy-duty container markets. Each 4 Cavity 3-Gallon Preform Mold is shipped with a full metrology report that guarantees wall-thickness concentricity within ±0.0075 mm, ensuring trouble-free downstream blowing.

Maintenance of the 4 Cavity 3-Gallon Preform Mold is simplified by quick-release manifold plates and standardized valve-gate components; a weekly two-hour PM schedule is normally enough to keep the 4 Cavity 3-Gallon Preform Mold running at peak efficiency. Global beverage and chemical packagers favor the 4 Cavity 3-Gallon Preform Mold for its robust design, consistent quality, and rapid ROI, often reaching payback in less than eight months when running two shifts.